How 3D scanning and metrology are transforming aerospace and defence efficiency

Few industries demand as much precision, reliability and accountability as aerospace and defence. From the wings of a passenger jet to the armour of a military vehicle, every component must meet stringent standards while withstanding extreme conditions. With pressure to accelerate timelines and reduce operational risks, advanced metrology, particularly 3D scanning and digital measurement solutions, enables manufacturers, MRO teams and defence contractors to stay ahead.

3D scanning in aerospace: Accelerating production

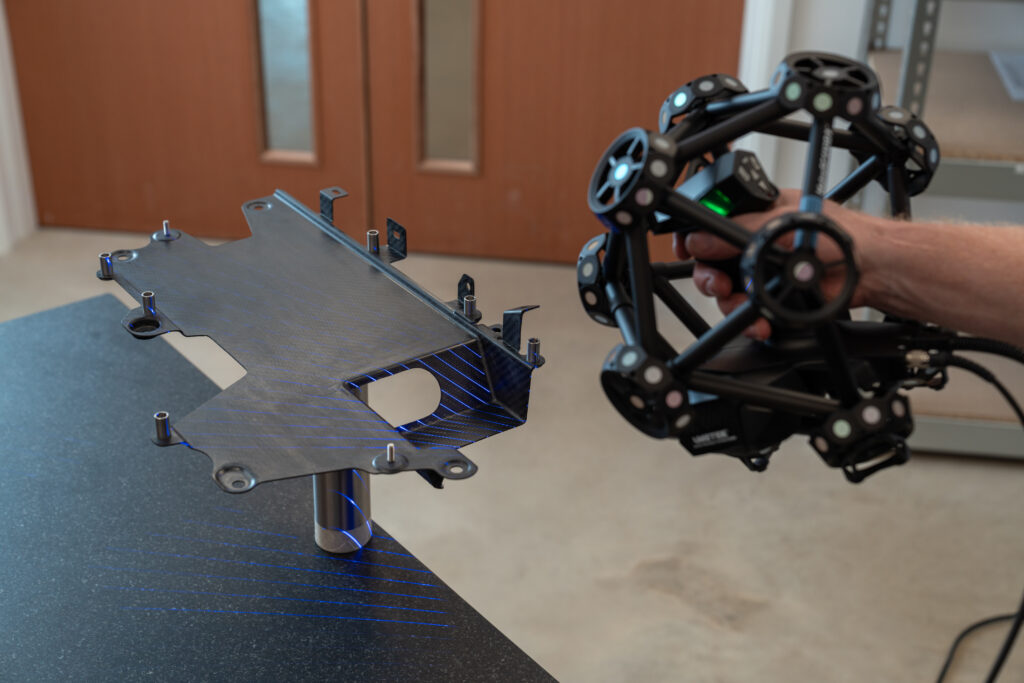

Traditional inspection methods struggle with the complex geometries of modern aircraft. Portable and automated 3D scanners now make it possible to:

- Reduce time-to-market with faster prototyping and design validation

- Improve quality control by capturing complex surfaces without fixturing

- Support additive manufacturing and lightweight composite parts

- Maintain global consistency by sharing scan data digitally across supply chains.

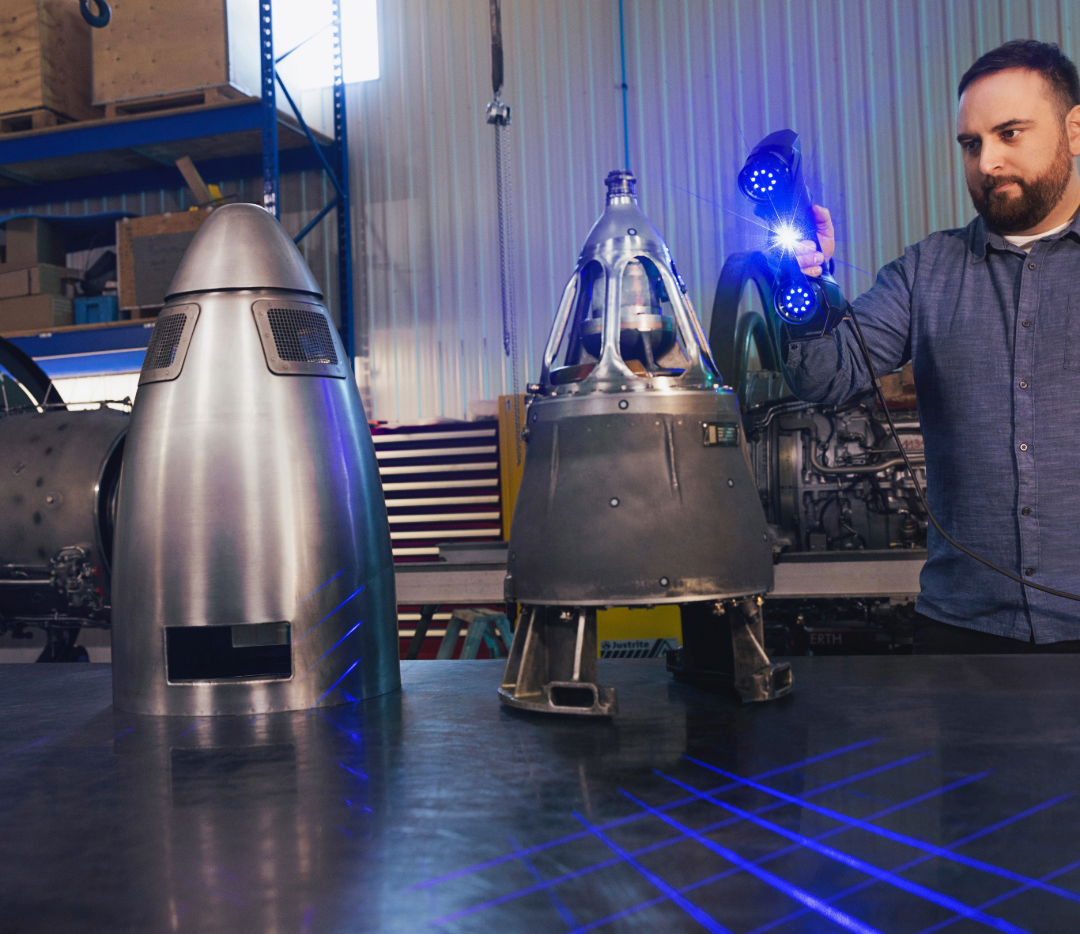

3D scanning in defence: Reinventing MRO and adaptation

Defence projects face unique challenges: ageing fleets, battlefield damage and mission-driven adaptations. 3D scanning delivers critical advantages in:

- MRO (maintenance, repair and overhaul): quickly scan damaged components for exact replicas or validated repairs

- Reverse engineering: replace legacy parts when OEM drawings or suppliers are unavailable

- Customisation: adapt equipment for specific missions with precision fit

- Forensics: capture digital evidence for operational analysis and training.

Security and compliance are essential. Alongside international frameworks such as ISO 17025, NIST SP 800-171 and ITAR/DDTC, UK defence contracts increasingly rely on accreditations like Cyber Essentials/Cyber Essentials Plus and the JOSCAR supplier accreditation register.

Market momentum: Why now’s the time

The global 3D scanning market is set to double in value by 2030, with aerospace and defence among its fastest-growing sectors. Key drivers include:

- Increasing part complexity (composites, additive manufacturing turbo machinery)

- Global supply chain pressures are encouraging digital-first solutions

- Demand for speed-to-field in defence and commercial programmes.

Now is the time for organisations to embed scalable metrology capabilities to future-proof operations.

Emerging technologies reshaping aerospace and defence

AI and machine learning

- Automatically detect defects and wear.

- Optimise scan paths for faster data capture.

- Predict maintenance needs from historical data.

Digital twins

- Enable predictive maintenance of aircraft and vehicles.

- Simulate mission scenarios virtually.

- Maintain a living digital record for lifecycle management.

Automation and robotics

- Fully automated scanning cells deliver inline inspection.

- Provide 100% part coverage and eliminate operator variability.

- Ideal for high-volume aerospace parts like turbine blades.

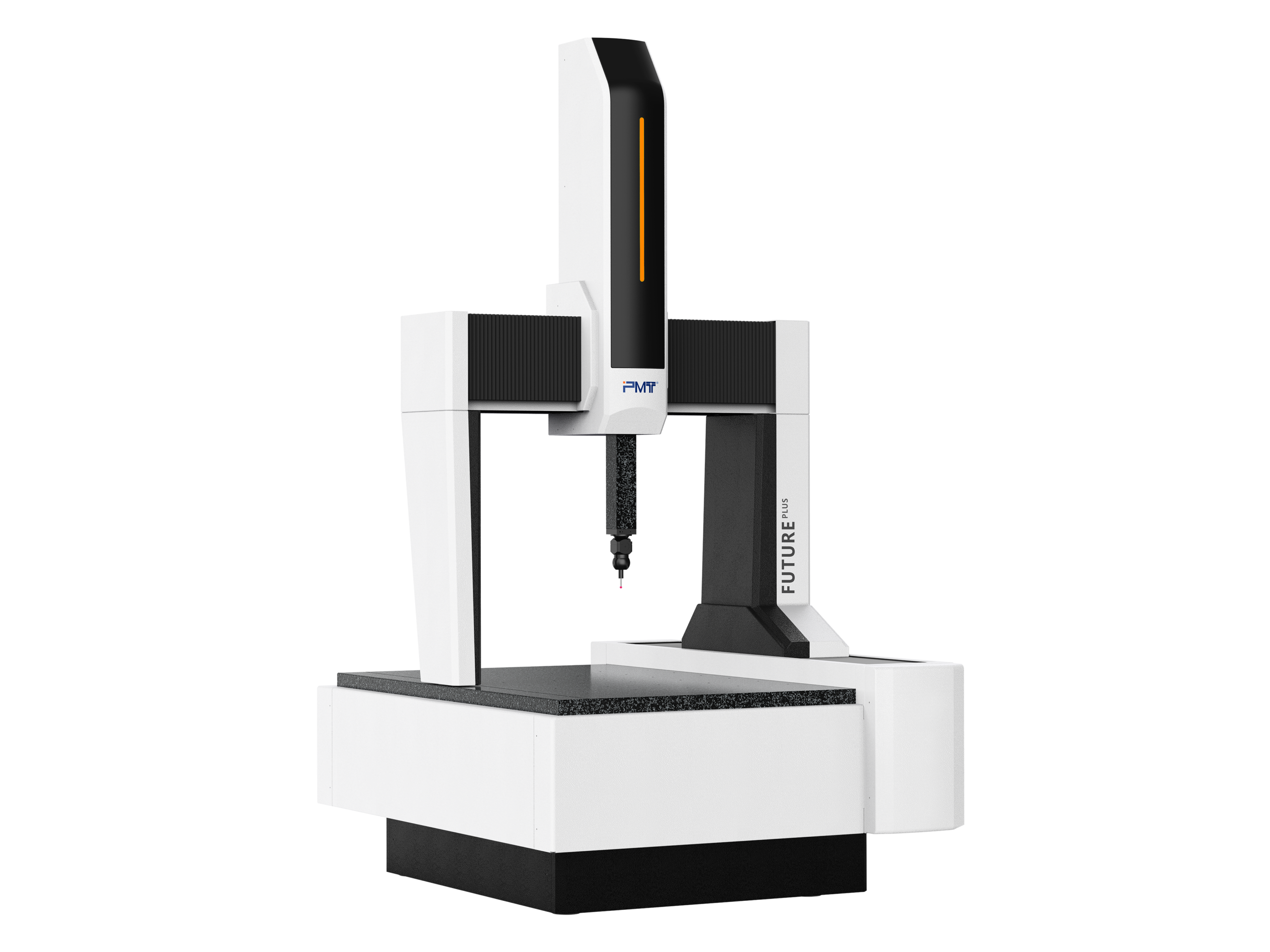

Structured-light and hybrid scanning

- High precision for complex geometries and composite surfaces.

- Bridges handheld flexibility with CMM-grade accuracy.

Secure data collaboration

- Cloud-based platforms enable global collaboration on sensitive projects.

- Encrypted systems ensure IP protection and compliance with defence standards.

Certification and trust: The peace of mind factor

For aerospace and defence, trust is non-negotiable. The selected metrology partner must deliver not only cutting-edge technology but also the assurance of compliance, security and resilience.

Measurement Solutions is Creaform’s trusted partner in the UK, providing customers with local expertise backed by the strength of a global leader in metrology. This partnership ensures that UK aerospace and defence organisations benefit from world-class technologies, supported by a team that understands the regulatory, compliance and operational demands of the sector.

Safeguarding people, processes and technology

Creaform’s Information Security Policy promotes a holistic approach, vetting people, processes and technology to manage risks and ensure customer data remains protected.

Key certifications and accreditations

- ISO/IEC 27001:2022 certified information security management system.

- ISO 17025 and ISO 10360: accredited calibration and metrology competence.

- ISO 9001 and ISO 14001 quality and environmental standards.

- NIST SP 800-171 compliant and CUI certified: cybersecurity for controlled unclassified information.

- DDTC registered and ITAR/CGP compliant: handling of controlled goods and defence technology.

- C-TPAT (Customs-Trade Partnership Against Terrorism): international supply chain security.

- Safe Contractor approved for assurance of health, safety, and ethical practices.

- CAGE Code 7EXZ5: recognised defence supplier code.

UK-specific standards

- Cyber Essentials/Cyber Essentials Plus: MoD-mandated cybersecurity assurance.

- JOSCAR registration: Used by UK primes such as BAE Systems, Leonardo and Rolls-Royce.

Resilient supply chains

As of 2024, Creaform has strengthened resilience by sourcing scanner components from North America and Europe, including critical parts like cameras and lasers. Software development and data storage are also kept within these regions, reducing geopolitical and cybersecurity risks.

Together, these certifications and policies provide customers with complete peace of mind: every scan, dataset and project is protected by world-class security, robust compliance and transparent sourcing.

Best practices for adoption

1. Start small: begin with handheld scanners for prototyping or MRO.

2. Scale smart: expand into automated solutions for production lines.

3. Prioritise compliance: ensure partners hold recognised certifications.

4. Integrate digitally: link metrology data into CAD, PLM or simulation platforms.

5. Invest in training: skilled teams maximise ROI and adoption success.

Conclusion: From production line to front line

Metrology is no longer just about measurement; it’s a strategic enabler. In both aerospace and defence, it accelerates production, extends asset lifecycles and ensures mission success.

By embracing AI, digital twins, automation and secure collaboration, organisations can achieve new levels of efficiency, agility and resilience.

As Creaform’s trusted UK partner, Measurement Solutions brings world-leading technologies together with local expertise, ensuring aerospace and defence organisations have a reliable, accredited and future-ready partner by their side.