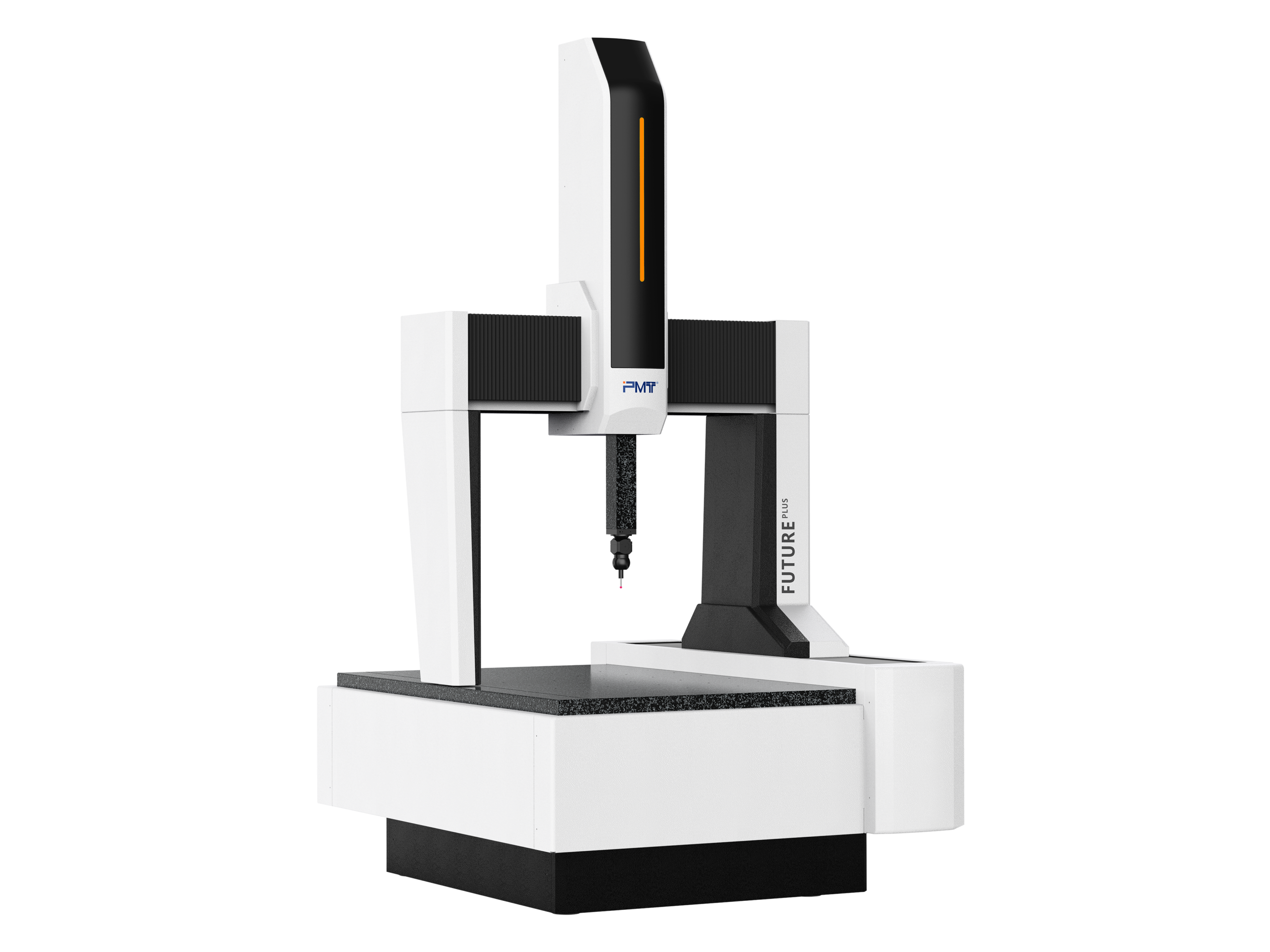

New PMT CMM range: Accurate and cost-efficient

As manufacturing and engineering environments evolve, businesses increasingly require dimensional measurement solutions that combine precision with practical investment. The new PMT bridge CMM range available in the UK from Manchester Metrology delivers high-accuracy measurement in a fixed, controlled format, providing businesses with the performance of a premium system at a more accessible cost than traditionally associated with bridge CMM technology. The machines provide a reliable foundation for workflows where accuracy, consistency, repeatability and stability are essential.

Accuracy

PMT bridge CMMs deliver repeatable measurement accuracy of up to 1.2 μm (0.0012 mm) depending on the model and configuration, providing businesses with the confidence that components and assemblies can be verified to very tight tolerances.

Model range, sizes and configurations

The PMT bridge CMM range includes three core ranges — PMT Future, PMT Future Plus and PMT Prime — and is available in a wide range of sizes and configurations, covering smaller machines suitable for compact components through to larger formats designed for substantial workpieces. This flexibility allows businesses to select a system that aligns with their operational requirements, whether measuring small precision parts, complex assemblies or large prototype components. The range ensures that businesses of varying sizes and sectors can access fixed, high-precision measurement without compromise.

Across all models, the range provides high‑precision measurement suitable for industrial production, prototyping and research applications. Repeatable accuracy is supported by rigid bridge construction, granite guideways and precision-engineered drive systems, which together ensure smooth, stable movement along all axes. These design features help minimise deformation, thermal variation and vibration, which are key considerations for sectors where tolerances are tight and measurement consistency is critical. Reliable data capture allows engineers and production teams to verify parts confidently, identify deviations early and maintain standards throughout the manufacturing process.

Bridge CMMs are particularly suited to applications where stable conditions and repeatable routines are essential. In the automotive, aerospace, precision engineering and research sectors, fixed systems support measurement of components, assemblies and tooling with consistent, comparable results. Laboratories and R&D centres benefit from PMT CMMs when developing prototypes, testing materials or verifying complex designs, especially when repeatable data is required across multiple measurement cycles. These systems help businesses maintain high operational standards and reduce risk in critical measurement processes.

By introducing the PMT bridge CMM range to the UK, Manchester Metrology is expanding its measurement technology offering, alongside established services that support a wide range of business requirements.

All PMT CMMs come supplied with Renishaw UCC controller, PH10 head, probe rack, CMM fixture kit, base plate and PC. Delivery, installation and calibration is included, while optional extras such as software, training and probe head upgrades are available.