Why flexible metrology cells like the CUBE-R M series are transforming modern manufacturing

Modern manufacturing is entering a new phase of transformation. Tighter tolerances, greater product variation and shorter development cycles are reshaping the demands placed on quality control. As a result, the conversation has shifted from whether to automate inspection to how to automate it in a way that remains flexible, scalable and resilient to change.

Yet many automated measurement systems on the market remain rigid, optimised for static, high-volume lines and are difficult to adapt once deployed. This creates friction for manufacturers who need to respond quickly to design updates, fluctuating volumes and evolving part families.

What manufacturers now need is a new category of automation: one that combines metrology-grade accuracy with the flexibility required for modern production environments. The new Creaform CUBE-R M series, available in the UK through Measurement Solutions Ltd (MSL), embodies exactly this shift.

Why flexible automated QC is becoming a priority

Across UK manufacturing, three pressures are converging:

- Shorter product lifecycles: design changes, variant expansion and engineering updates are more frequent than ever

- Higher-dimensional requirements: customers and regulators demand tighter tolerances and more reliable traceability

- Skills shortages: metrology and robotics expertise are increasingly scarce, especially for SMEs.

Rigid automated systems can struggle under these conditions because when the line changes, the system cannot easily change in tandem. This is where the CUBE-R M series, with its modular, upgrade-ready design, offers a different path.

A metrology automation platform built for real-world change

Rather than locking manufacturers into a fixed footprint, the M series provides a scalable automation platform.

Three turnkey measuring cell sizes

Designed for different part families:

- M2™ — parts up to 2 m

- M3™ — up to 3 m

- M4™ — up to 4 m.

These cells slot into existing shop-floor layouts while providing room for future growth. As production needs evolve, the system can evolve alongside.

Custom configurations for unique UK use cases

MSL regularly supports integration for:

- Automotive castings and BIW

- Aerospace aluminium structures

- Composite components

- Large fabricated assemblies

- Defence-sector parts requiring traceability

- Industrial machinery components.

This means UK manufacturers can adopt automated inspection in a way that suits their current footprint and future direction.

Productivity through smarter parallelisation

Traditional automated metrology systems often follow a linear flow: scan → stop → process → move. The M series breaks that model by enabling parallel scanning and data processing, reducing cycle times by up to 40% through Automation-Process. For UK manufacturers, that translates into:

- Higher sampling rates

- Earlier detection of process drift

- More robust SPC

- Better control of variation

- Higher throughput without expanding labour.

In other words: more insight, without slowing the line.

Designed for the realities of the factory floor

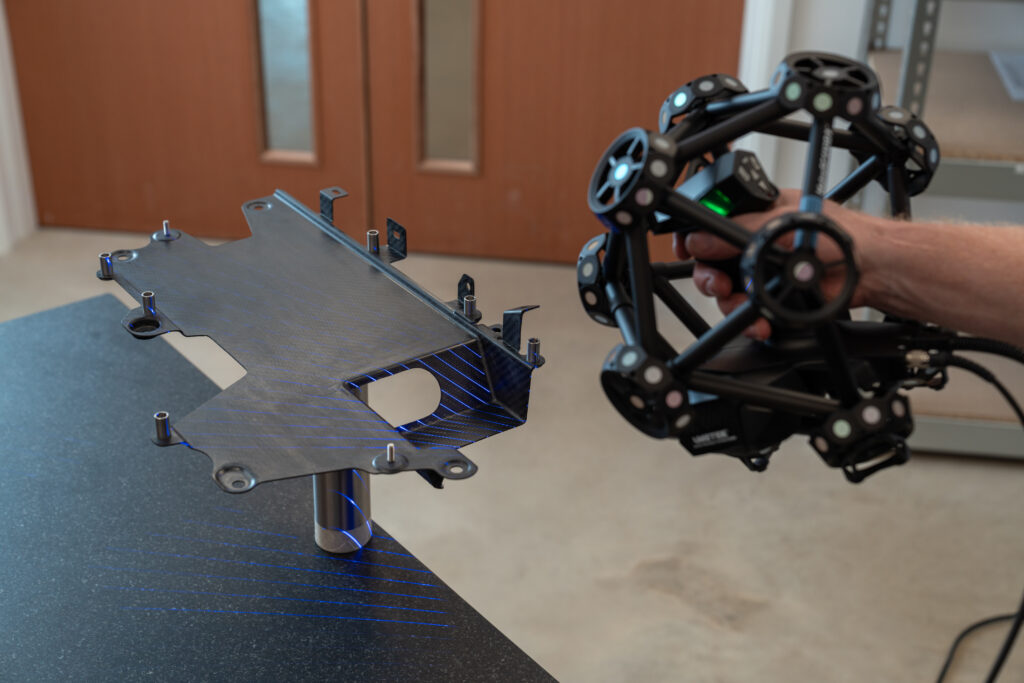

The shop floor is a tough environment: vibration, movement, temperature shifts, forklift traffic and constant change. The MetraSCAN 3D-R inside the CUBE-R M series is engineered specifically for these conditions.

Metrology-grade accuracy where it matters

- 0.025 mm accuracy in real shop-floor conditions thanks to dynamic referencing

- Up to 69 laser lines for fast, high-resolution scanning of trims, edges, and sheet-metal boundaries

- 0.015 mm resolution for detailed feature capture

Blue laser technology

Ideal for reflective, shiny or mixed-material parts, common across automotive and precision engineering sectors.

This robustness allows many UK manufacturers to shift inspection from the metrology lab to the production floor without sacrificing accuracy.

Hardware flexibility matched by software freedom

The M series includes ‘Automation’, Creaform’s digital twin programming environment. Operators can:

- Build and simulate inspection plans offline

- Optimise robot paths

- Check for collisions

- Adjust scanning parameters before running on the real cell.

Crucially, no robotics or metrology expertise is required, a major win for UK factories facing skill shortages.

Flexible software workflow designed for real production environments

The CUBE-R M series is engineered to integrate smoothly into modern manufacturing workflows. Its Automation software, part of the Creaform Metrology Suite, provides a software-independent environment, allowing manufacturers to work with the platforms and reporting systems they already rely on.

The system supports:

- Industry-standard data formats for easy transfer into leading inspection and CAD platforms

- A digital twin environment for offline programming, collision checking and scan-path optimisation

- Automated execution workflows that separate program creation from operation, reducing dependency on specialist skills

- Simple connectivity to existing quality processes, allowing manufacturers to maintain established downstream operations.

The result is a metrology automation solution that fits into existing digital ecosystems, rather than forcing a rebuild of established inspection workflows.

Real-world proof: Unipart Powertrain Applications’ automated measurement strategy

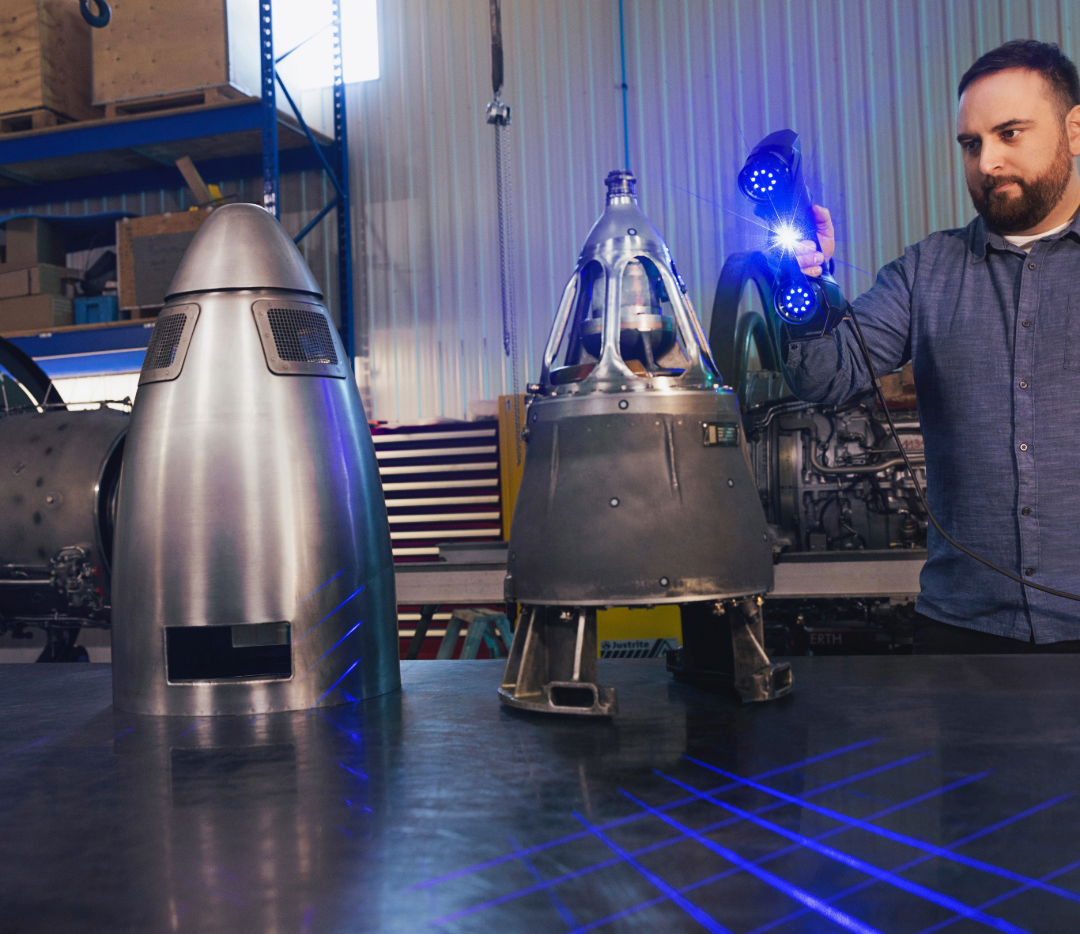

One of the clearest demonstrations of why flexible automated metrology matters comes from Unipart Powertrain Applications (UPA), a major UK manufacturer that has steadily evolved its measurement capability with MSL’s support. The experience of UPA shows how automation can be adopted step by step, scaled over time, and deliver meaningful productivity gains almost immediately.

A high-complexity workflow that needed to go further

UPA used Creaform 3D scanning for years to measure complex, high-detail components. The technology delivered the accuracy they required, but the frequency and intricacy of the inspections meant the workflow demanded significant manual input across two shifts. As inspection volumes grew, resourcing constraints became increasingly challenging.

The turning point: Automating the existing workflow

Rather than replacing equipment or restructuring processes, UPA chose to automate what already worked. Partnering with MSL, the company transformed its manual MetraSCAN inspection routine into a fully automated system by integrating:

-

A Universal Robot (UR10)

-

A custom-developed MSL I/O module

-

Their existing MetraSCAN 3D

-

A linear track and part manipulator for full-coverage scanning.

The result was a closed-loop automated scanning workflow, seamlessly connecting robot, scanner and PolyWorks for hands-free inspection.

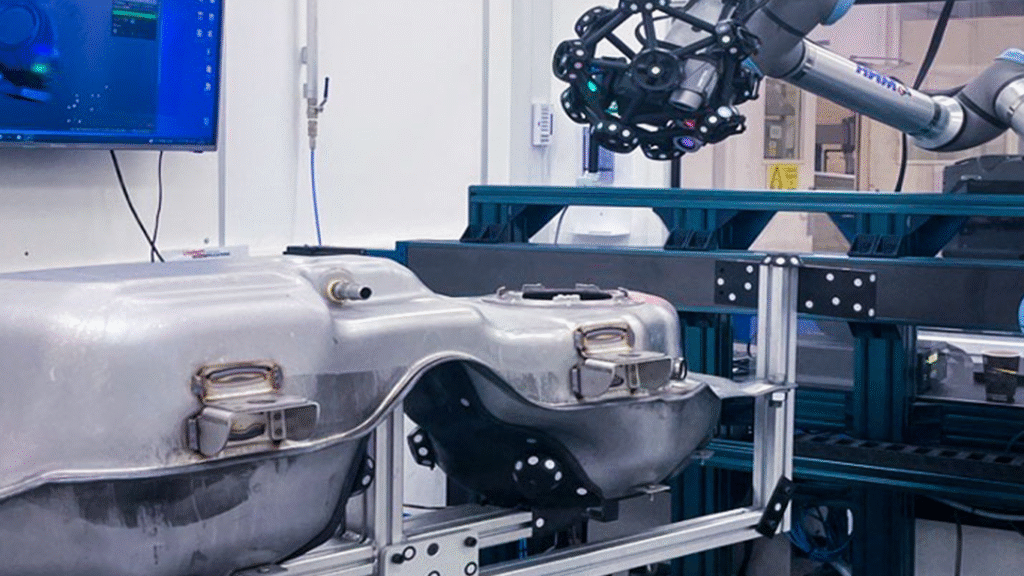

The outcome: More output, less manual effort

With automation in place, UPA now achieves:

-

Almost zero manual scanning input

-

Direct SPC reporting into PolyWorks for real-time quality insight

-

Earlier detection of issues through higher sampling rates

-

Increased part throughput without additional labour.

As Nathan Smith, Manufacturing Engineer at Hyperbat (a joint venture between WAE and Unipart), explains: “Using the MetraSCAN 3D as part of our automated measurement strategy provides an innovative way of part inspection whilst maintaining accuracy, efficiency and versatility.”

And from MSL’s own automation team: “UPA are now increasing inspection output and efficiency, with a reliable, repeatable and cost-effective automated solution.”

How this relates to the CUBE-R M series

UPA’s journey highlights several principles that are central to the CUBE-R M series:

-

Automation doesn’t require starting from scratch: the M Series supports staged adoption and gradual scaling, just like UPA’s approach

-

Flexibility is essential: UPA needed a system that adapted to evolving production demands rather than locking it into rigid workflows

-

Expert integration unlocks value: UPA’s success depended on MSL’s ability to combine hardware, software and workflow engineering into a cohesive solution.

This gradual, adaptive path to automation mirrors the philosophy behind the new CUBE-R M series, which is built to evolve with the needs of modern production rather than forcing a one-size-fits-all approach.

Why UK manufacturers choose MSL as their automation partner

Purchasing an automated metrology cell is not just equipment acquisition; it’s a long-term strategy. MSL supports customers with:

- Automation consultancy

- Proof-of-concept studies

- Integration and installation

- Training and workflow optimisation

- Ongoing service, calibration and technical support.

Combined with Creaform’s proven technology and ISO 17025-certified accuracy, this gives UK manufacturers confidence that automation will deliver lasting value.

Conclusion: A future-proof approach to automated inspection

Flexible automated quality control is no longer optional; it’s becoming foundational to modern manufacturing. The CUBE-R M series, brought to the UK by MSL, offers:

- Flexibility

- Scalability

- Metrology-grade accuracy

- Ease of programming

- Software independence

- Long-term support.

And with real-world success stories like UPA, UK manufacturers can see exactly how automated metrology delivers productivity, consistency and confidence, today and in the future.