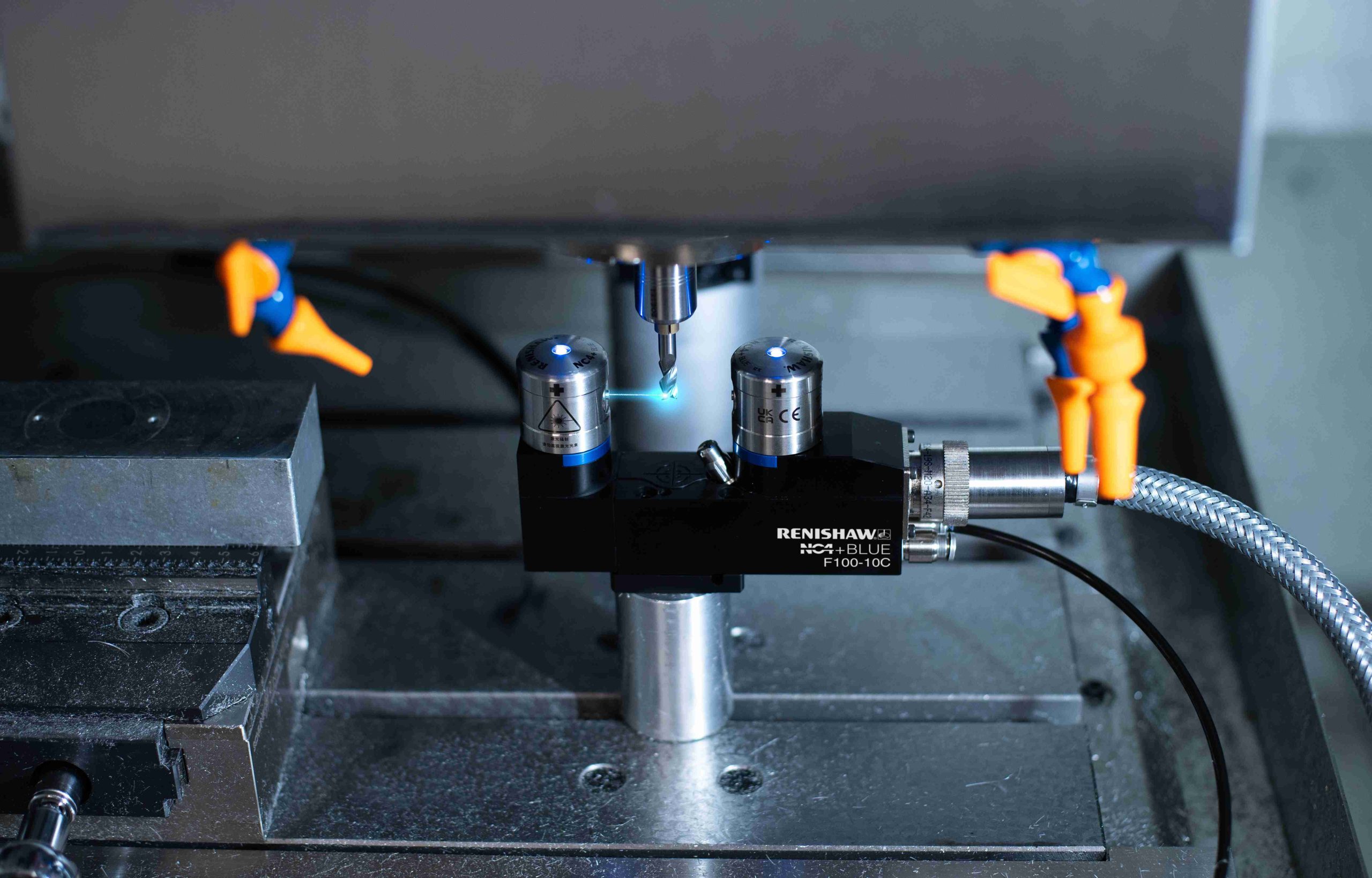

A new benchmark with third-generation NC4+ Blue laser tool setters

Renishaw unveiled its third-generation NC4+ Blue laser tool setter models at the recent EMO 2025 exhibition in Hanover, marking a significant milestone in the company’s continuous pursuit of innovation in precision measurement technology. According to the company, its new F100 and F100-10C models set a new benchmark for non-contact tool setting and demonstrate Renishaw’s dedication to helping manufacturers achieve higher levels of accuracy, reliability and efficiency in CNC machining.

The NC4+ Blue series has long been regarded as a trusted solution for tool measurement and breakage detection, says Renishaw, and the introduction of the third-generation systems further advances this reputation. With an optimised optical and mechanical design, the NC4+ Blue F100 models achieve repeatability of ±0.1 µm (2σ). Performance of this level is critical in sectors such as aerospace, automotive, electronics and medical device manufacturing, where consistent, micron-level accuracy is essential to achieving high-quality parts and tight tolerances.

By identifying even the smallest tool defects before machining, NC4+ Blue systems help manufacturers prevent downstream quality issues. This capability contributes to improved surface finishes, extended tool life and reduced scrap rates—key benefits that translate directly into greater production efficiency and lower overall manufacturing costs.

The F100 models’ compact footprint make them suitable for machine tools with limited working space, allowing manufacturers to integrate high-performance tool setting within smaller machining environments. Despite their reduced size, the systems maintain the high-speed, high-precision performance that users of Renishaw’s NC4+ Blue technology have come to expect.

Renishaw has also improved the environmental efficiency of its new systems by optimising air flow through the unit. The redesigned barrier air system reduces air consumption by more than 50%, meaning the tool setters require less energy for air compression and lower the associated operational costs. This development reflects Renishaw’s broader commitment to supporting sustainable manufacturing practices and designing products that deliver measurable energy savings throughout their lifecycle.

As part of the wider NC4+ Blue portfolio, the F100 and F100-10C models continue to deliver high-speed, non-contact tool setting and tool breakage detection, both of which are essential for maintaining process control in automated machining environments. The use of Renishaw’s industry-first blue laser technology allows for superior accuracy in measuring small or reflective tools, overcoming limitations that often affect traditional red laser systems.

To ensure long-term reliability, the F100 systems incorporate Renishaw’s proven MicroHole aperture and PassiveSeal mechanism. These design features protect the optical components from contamination and coolant ingress, ensuring consistent performance even in workshop environments. As a result, manufacturers benefit from reduced maintenance requirements and improved system uptime.

“At Renishaw, we strive to develop technologies that make a meaningful difference to our customers,” says Steve Petersen, Product Management and Marketing, Machine Tool Division. “The new third-generation F100 NC4+ Blue models exemplify this approach—combining sub-micron-level precision with a compact, energy-efficient design. These systems help manufacturers achieve consistent quality while reducing operational costs, reinforcing our commitment to excellence in metrology.”

In addition to the hardware advancements, Renishaw’s macro software for the NC4+ Blue enables users to automate tool measurement and set-up routines. The software offers a wide range of non-contact tool setting cycles that simplify complex processes, enhance repeatability and reduce the potential for human error. By integrating seamlessly with CNC machine controls, the system allows manufacturers to shorten set-up times, improve machine utilisation and maintain consistent production quality across multiple shifts.

At EMO, visitors had the opportunity to see live demonstrations of the NC4+ Blue F100 models and speak directly with Renishaw’s technical experts. The event highlighted how these next-generation systems supported manufacturers in achieving right-first-time production through enhanced measurement accuracy and process control.