A new generation in multi-sensor metrology

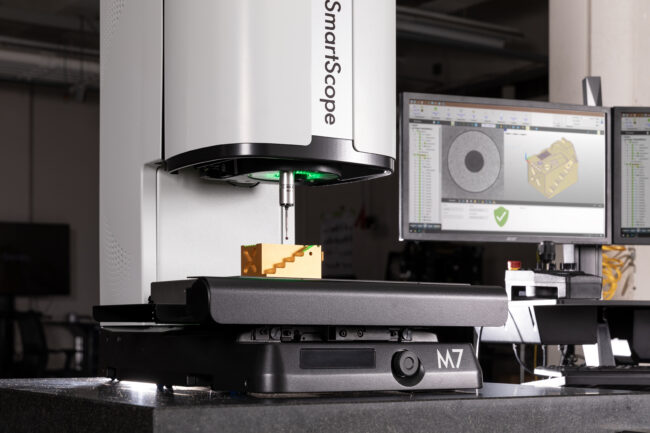

OGP UK, part of the Carfulan Group, has released its SmartScope M-series, which the company says represents a significant step forward in 3D multi-sensor measurement technology for modern manufacturing.

The M-series builds on OGP’s heritage in optical metrology, introducing a system that combines optical, tactile and laser measurement options within a single platform. At its core is the patented IntelliCentric-M optical system, a fully telecentric fixed-lens design paired with a 20-megapixel digital metrology camera and electronically controlled aperture. This configuration provides high-resolution imaging with minimal distortion, enabling consistent edge detection and precise dimensional analysis.

A key development in the M-Series is the introduction of virtual zoom technology, which replaces conventional mechanical zoom mechanisms. By removing moving components, virtual zoom allows instant magnification changes and contributes to faster measurement routines with reduced maintenance requirements. The result is a system designed to operate efficiently in demanding production environments.

Lighting is another area of focus. The M-Series incorporates the ‘SmartRing’ light for flexible, multi-angle illumination, alongside a full LED backlight and coaxial surface light. These features offer controlled, stable lighting conditions for inspecting a variety of surfaces and materials, improving repeatability and image quality.

For greater measurement flexibility, the system supports multiple sensors, including optional tactile probes and laser devices. Additional 4th and 5th-axis rotary stages are available for parts requiring full rotational inspection. This range of capabilities allows the M-series to perform both contact and non-contact measurement of complex geometries, adapting to the requirements of precision component manufacturers.

The M-series is powered by ZONE3, OGP’s advanced metrology software platform. ZONE3 combines intelligent edge detection algorithms with parallel processing to optimise throughput and accuracy. It provides a unified environment for managing sensor data and developing automated measurement routines.

Available in two benchtop and two floor-standing configurations, the SmartScope M-series is designed to accommodate a wide range of component sizes and inspection tasks. It reflects the growing trend towards integrated, multi-sensor metrology systems capable of handling increasingly complex production demands.

As manufacturing continues to evolve, systems like the M-series highlight how measurement technology is adapting to support higher standards of accuracy, repeatability and efficiency. For precision engineers and machine shops looking to enhance quality control, the arrival of this new platform signals another step in the ongoing advancement of smart manufacturing.