Enabling high-precision re-manufacturing with Peel 3D scanning

NS85 is a UK-based high-performance engineering firm specialising in the design, development, and re-manufacturing of bespoke components, particularly braking systems, for motorsport, high-end automotive, heritage vehicles and specialist low-volume applications.

With a reputation for solving complex engineering challenges, NS85 blends advanced mechanical design with modern manufacturing techniques to deliver critical components where no OEM support or CAD data exists. Its core strengths lie in:

• High-performance brake system design from concept to production

• Reverse engineering and legacy part recreation

• Custom part re-manufacturing

• Performance-driven innovation under tight tolerances

NS85’s agile team operates at a high technical standard, often bridging the gap between concept and manufacturable reality for customers who need precision components that outperform factory originals.

Objective

NS85 aimed to enhance its internal capability for reverse engineering by bringing 3D scanning in-house, particularly to support:

• Re-manufacturing of legacy parts where geometry is complex and data is non-existent

• Accelerating design workflows by reducing dependency on external scanning providers

• Improving model confidence and reducing prototyping cycles

• Capturing real-world geometry with engineering-grade accuracy

Although NS85 does not typically offer 3D scanning as a commercial service, it does play a critical role in the company’s design process, enabling it to reimagine existing parts with modern materials, design improvements and manufacturing methods.

“Our job is often to make the impossible practical, especially when there’s no blueprint to start from,” says Nick Stevens, Director at NS85.

Application in the workflow

Re-manufacturing heritage and obsolete components

Much of NS85’s engineering revolves around solving problems for parts that are no longer produced, often bespoke or decades old. Brake callipers, in particular, present a challenge: complex internal and external geometry, no drawings and tight installation constraints. From historic race cars to rare performance road vehicles, NS85 uses Peel 3D scanning technology from Measurement Solutions Ltd (MSL) to:

• Capture external and internal part geometry

• Generate watertight meshes for comparison and modelling

• Produce CAD-ready data for remanufacturing and CNC machining

• Build an accurate packaging model to ensure parts that fit first time

“We’ve reverse-engineered multiple heritage motorsport calipers using the Peel scanner,” explains Nick. “The accuracy of the scan data gives us full design freedom while maintaining tight form and fit tolerances.”

Clean-sheet design and performance re-engineering

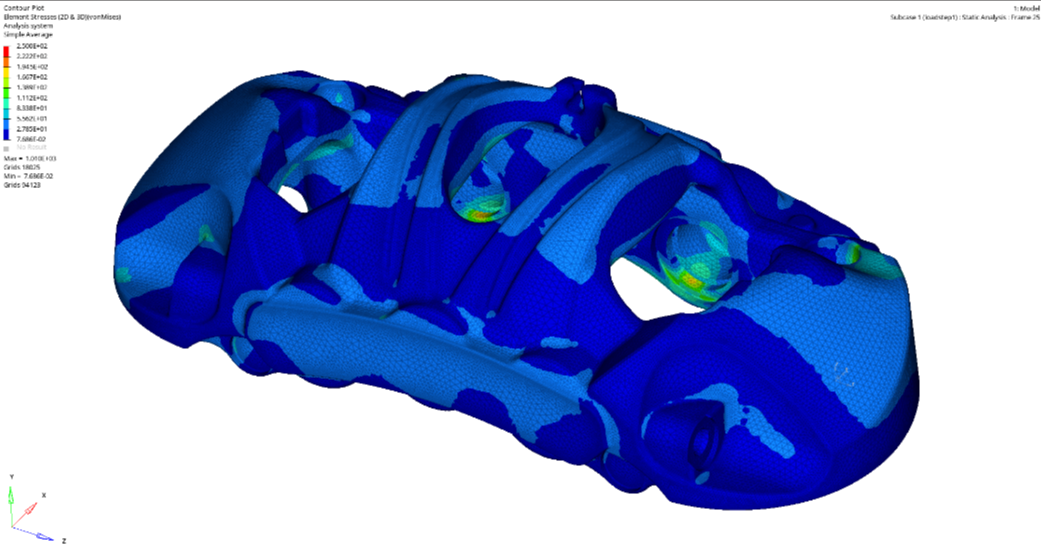

In an Innovate UK-supported project, NS85 applied the Peel 3D scanner to re-engineer Porsche 911 callipers from the modern 991/2 era of 911 models:

• The scanned data was used to create a space envelope model that defined critical geometry and packaging constraints

• Topology optimisation was performed to remove weight without compromising strength

• A machined billet aluminium prototype was produced

• An additively manufactured version was simulated to test performance under extreme conditions

This iterative loop of optimise > design > validate would have been more time consuming and with higher risk of inaccuracy without the confidence provided by high-quality scan data at the beginning.

The challenge

Prior to using Peel 3D from MSL, NS85 faced several common roadblocks typical in low-volume, legacy part engineering:

• No original CAD or drawings, especially in motorsport and heritage applications

• Manual measurement was insufficient for parts with organic shapes or multi-axis geometries

• Outsourcing scans meant delays, added costs, and less control

• High risk of error when building from incomplete or approximate measurements

For a company that prides itself on high-accuracy outcomes, these issues were limiting both workflow speed and final part quality. The price point and capabilities made Peel the right choice for NS85. Going from no scanner to this scanner felt like a huge step change for the company and has been a game-changer for business. Peel allowed the team to work faster, more independently, and with full ownership over its geometry capture and modelling processes.

Peel 3D

After testing different options, NS85 chose Peel 3D from MSL for its combination of:

• Ease of use for small internal teams

• Accuracy suitable for engineering-grade workflows

• Affordability compared to metrology-grade systems

• Adaptability across different projects and materials

Results and impact

Bringing 3D scanning in-house delivered immediate, measurable benefits:

• Faster turnaround times for component re-manufacturing and prototyping

• Greater confidence in model accuracy and part fit

• Reduced costs and delays by eliminating third-party scanning dependencies

• Improved collaboration and communication with precise visuals and shared models

• Enhanced ability to innovate, by giving engineers more time and data to develop better solutions

Looking ahead

To further strengthen its re-manufacturing pipeline, NS85 plans to:

• Integrate dedicated Scan-to-CAD software for faster solid model creation

• Expand scanning to more complex assemblies, including multipart component systems

• Explore higher-resolution scanning for critical-tolerance or inspection-heavy projects

For now, Peel 3D offers a sweet spot: powerful enough for reverse engineering work, and simple enough to use in a lean, fast-moving environment.

The final outcome

NS85’s investment in Peel 3D has fundamentally improved how they handle legacy parts, enabling more precise, repeatable, and confident engineering outcomes across every stage of its workflow.

“3D scanning has completely changed our process,” says Nick. “Peel was the enabler; it gave us the confidence to design accurately, get it right first time, and deliver better products faster. For a business like ours, it’s the perfect fit, not just technically but financially as well. For what we’re doing now, Peel is perfect.”