Gauging innovation at Control 2025

In May, all roads led to the Control 2025 exhibition in Stuttgart, with the Measurement & Manufacturing team among thousands making the pilgrimage to this metrology extravaganza.

The Control exhibition has grown to become the who’s who of metrology, with the 37th edition hosting 500 exhibitors across four halls. In total, over 20,000 visitors from 70 countries flocked through the doors to get a glimpse of the latest and greatest in metrology innovation. Donned in suitably comfortable footwear, the Measurement & Manufacturing team trawled every aisle to unearth never-before-seen ways of making measurement faster, easier and smarter.

The stand of Hexagon was exceptionally crowded, with hordes of visitors surrounding the exhibits. Key among them was the new Leica ATS8000 laser tracker, which cuts the inspection time of large items such as aircraft structures, ship hulls and wind turbines from hours to just minutes. High-accuracy reflector-less scanning at distances of up to 40m powered by patented TruePoint technology means no scaffolding or target placement is necessary.

Also attracting much attention was Hexagon’s PRESTO quality station (photo, above), a turnkey measurement cell which, at Control 2025, was measuring the front end of an Oracle Red Bull Racing Formula 1 car. Shown featuring Hexagon’s new HYPERSCAN optical tracker with 3D scanning device, even non-metrologist shop-floor operators can improve efficiency with high-speed, high-resolution part scanning, supported by simple set-up and easy programming.

Another star product introduction was the Hexagon Maestro next-generation CMM. Fast, easy to use, fully digital and scalable, the machine was busy measuring an alloy wheel. According to the company, its new Maestro is the fastest CMM in the world, surpassing the previous fastest machine, Hexagon’s Global S. Jörg Deller, General Manager – Stationary Metrology Devices and MTM, revealed that a speed comparison involving the Maestro and Global S measuring an identical motorsport component, showed the former to be significantly faster. The Global S completed the measurement routine in 140 seconds, while the Maestro took only 90 seconds: 35% quicker.

Points of distinction

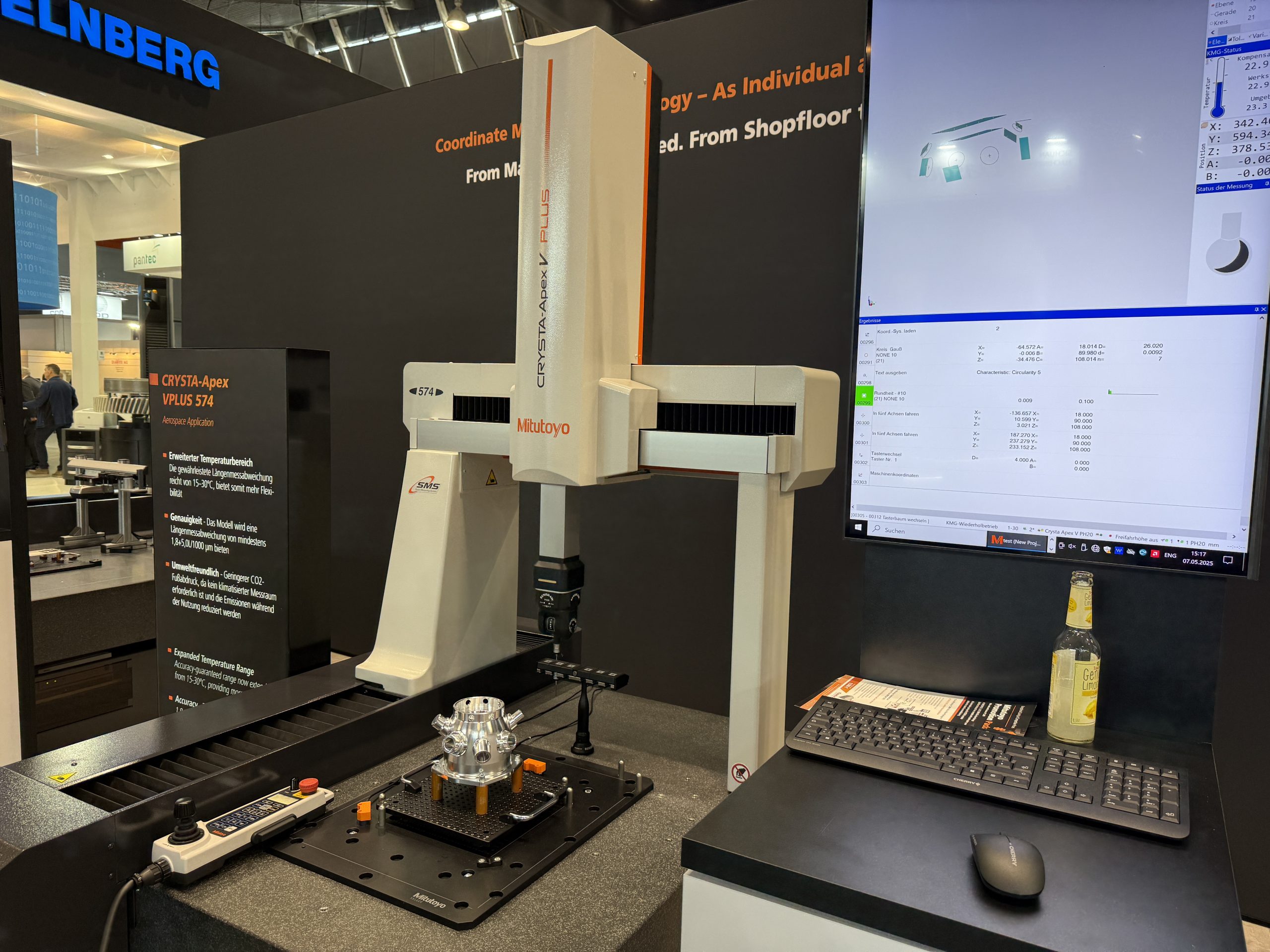

Among other new CMMs catching the eye at Control 2025 was the CRYSTA-Apex VPlus 574 from Mitutoyo (photo, below). Measuring a complex aerospace part at the show, the machine is ready for use in a smart factory environment with its temperature sensors for machine and workpiece compensation offering an extended range of 15-30°C. Using Mitutoyo’s ABS scales, the CRYSTA-Apex VPlus 574 has a high resistance to environmental conditions and does not require homing upon start-up. Billed as a future-proof investment, Mitutoyo says the high-accuracy, high-speed, high-acceleration CMM is capable of tackling almost any task thanks to its ability to change or add probe systems and software with ease.

LK Metrology was also promoting a new CMM suitable for shop-floor use in the shape of its new Altera SF (Shop Floor). The Altera SF withstands temperature shifts, vibration and dust without compromising its lab-grade accuracy, reports LK. On the stand, Sales & Marketing Co-ordinator Adam Tomlinson pointed out the presence of 360° status lights on top of the machine, while operator safety devices such as light curtains are optionally available.

Another stand-out CMM at Control 2025 was Wenzel’s new LH1210. Measuring a crankshaft at the exhibition, Wenzel developed this hybrid machine to offer greater measuring accuracy and speed. The LH1210 can support tactile measuring systems such as the Renishaw REVO five-axis measurement system and optical sensor solutions like the Wenzel LS 150, as well as the company’s CT solution for non-destructive metrological testing.

A good example of the portable CMM technology on show was the new PMT GAMMA, which is available in the UK from Manchester Metrology. Designed for high-precision, flexible and real-time inspection/measurement, PMT Gamma 3D measuring arms are built with lightweight aerospace-grade carbon fibre and offer enhanced stability and usability with their dual-suspension support structure. The range includes three models catering to various budgets and applications.

Leap forward

With FARO’s new Leap ST 3D handheld scanner, the company is very much focusing on application versatility. Peter Bambridge, Senior Account Manager at Faro UK, was on hand to demonstrate this new compact, high-accuracy scanner with no less than five operating modes: ultra-fast scanning for speedy coverage in the measurement of part features; hyper-fine scanning for capturing details of complex objects with maximum resolution; photogrammetry to maintain best accuracy over large objects; deep-hole scanning for hard-to-reach areas and holes; and large-area scanning for capturing sizeable features.

On the opposite side of the aisle sat Keyence, which was keen to showcase the virtues of the company’s new VL-800 series 3D Scanner CMM, the first in its line-up to feature 3D-AI for the effortless acquisition and analysis of high-quality 3D data. According to Konstantin Otto, Area Product Sales Manager, the system intelligently recommends optimal scanning, stitching and measurement methods based on the shape of the part under scrutiny.

The stand of Micro-Epsilon showcased the company’s new 3D Profile Unit, which enables smart 3D evaluation and output of stitched 2D/3D laser line profile data. In effect, the 3D Profile Unit aids the measurement of complex geometries by organising several laser scanners into a common co-ordinate system. This capability makes it possible to measure and inspect entire outer contours, undercuts and thickness volumes.

Another neat innovation could be seen on the stand of Marposs. According to the company, SMARTNet is more than just a fast network; it’s a smart, plug-and-play architecture created to simplify connections, minimise set-up and reduce costs. On the stand, Global Marketing Manager Mariangela Bettini said SMARTNet’s fully digital backbone makes measurement networks easier to configure, faster to maintain and more intelligent.

X marks the spot

According to Andreas Graf, Project & Sales Engineer at Werth Messtechnik, users of the company’s new and ultra-compact Tomoscope XS Plus 230 can solve even more measurement tasks faster, more accurately and therefore more economically using X-ray CT (computed tomography). Werth says its long-life transmission sources offer five times faster measuring speed and better economy than systems with conventional X-ray sources. Said to be the most powerful transmission source on the market with up to 140W, the Tomoscope XS Plus 230 is suitable for applications such as the measurement of prismatic battery cells used in the automotive or e-bike industries.

A further new offer in this technology area was present on the stand of Zeiss. The Metrotom 800 320kV is designed for the high-precision inspection of dense materials like Inconel, cobalt chromium and additively manufactured metal parts or multi-material assemblies. Robert Zarnetta, Head of Customer Segment Management, suggested that the Zeiss Metrotom 800 – now with 320kV in the X-ray range – is ideal for the quality assurance of turbine blades.

Eyeing the future

Taking the spotlight on the stand of Vision Engineering was its new EVO Cam HALO digital microscope. Carrying the strapline ‘4K inspection made easy’, the company says EVO Cam HALO digital provides ultra-HD image quality, supported by precision and versatility. The microscope features intelligent features, such as automatic lens identification and a super-wide dynamic range for brightness and contrast. The booth also featured a ‘portal into the future’, with Group Sales & Marketing Director Paul Newbatt present to explain a number of forthcoming innovations in digital 3D visualisation. These included a system that performs eye pupil tracking to create an advanced 3D stereo image on a flat screen, while another innovation highlighted the splitting of a mono image into a stereo image, providing an extra dimension without requiring the operator to perform any guesswork.

The theme on the stand of Mahr was ‘discovering optical metrology’, as highlighted by the innovations on display. In particular, with the acquisition of Optosurf, Mahr has expanded its portfolio to include scattered light technology. Several such devices were presented for the first time in Stuttgart as part of the MarSurf3D family. For example, it is possible to integrate the MarSurf3D Sensor OS 500 scattered light sensor into the control systems of machines like grinders or linishers to measure roughness and waviness exactly where it matters: directly inline.

Accretech used Control 2025 to highlight its Opt-Scope NEX non-contact surface roughness/texture and contour measuring machine, which was making its debut appearance in Europe. Suitable for high-end applications, including medical parts, the Opt-Scope NEX can measure fine surface roughness and geometry at nano- and sub-nanometre-level. Key here, explained the company’s Regional Director for North Europe Tim Wood, is the use of white-light interferometry that takes advantage of Accretech’s proprietary DEAP envelope/absolute phase detection algorithm.

True to form

Making its global launch on the Bowers stand was the new Figura range of contour, form and roundness measurement machines. Expertly explained by Product Development Manager Emma Bramley, feature-rich Figura machines are fast, easy-to-use and offer single-figure micron accuracy. The Figura RD is capable of high-accuracy measurements that include roundness, cylindricity, straightness, concentricity, flatness, full run-out, parallelism and perpendicularity, while the Figura CR is for contour, surface finish and roughness. According to Bowers, market differentiation arrives courtesy of the capabilities provided by the integrated measurement analysis software.

As many would expect at a metrology exhibition, there was a plethora of industry-familiar measuring instruments on display. Stand-out exhibitors here included Insize UK with its wide range of quality bore gages, hardness testers and hand tools. Catching the eye was a new vision measuring system, launched at the show, which will be available in the UK market in 2026/2027.

Exhausted but enlightened with new knowledge and a vision of the future, the Measurement & Manufacturing team headed home to begin looking forward to the 38th edition of Control, set to take place on 27-30 April 2027.