Hardness testing: Go hard or go home

Hardness testing remains among the most important measurement processes in today’s demanding manufacturing arena, underpinning quality, performance and compliance across numerous vertical sectors. Whether in automotive, aerospace or energy, hardness testing offers a rapid and reliable means of assessing crucial material properties such as strength, wear resistance and ductility. Applications extend from aircraft landing gear to automotive powertrain components; essentially, any heavy-load parts where product integrity and safety are paramount.

Make the smart choice

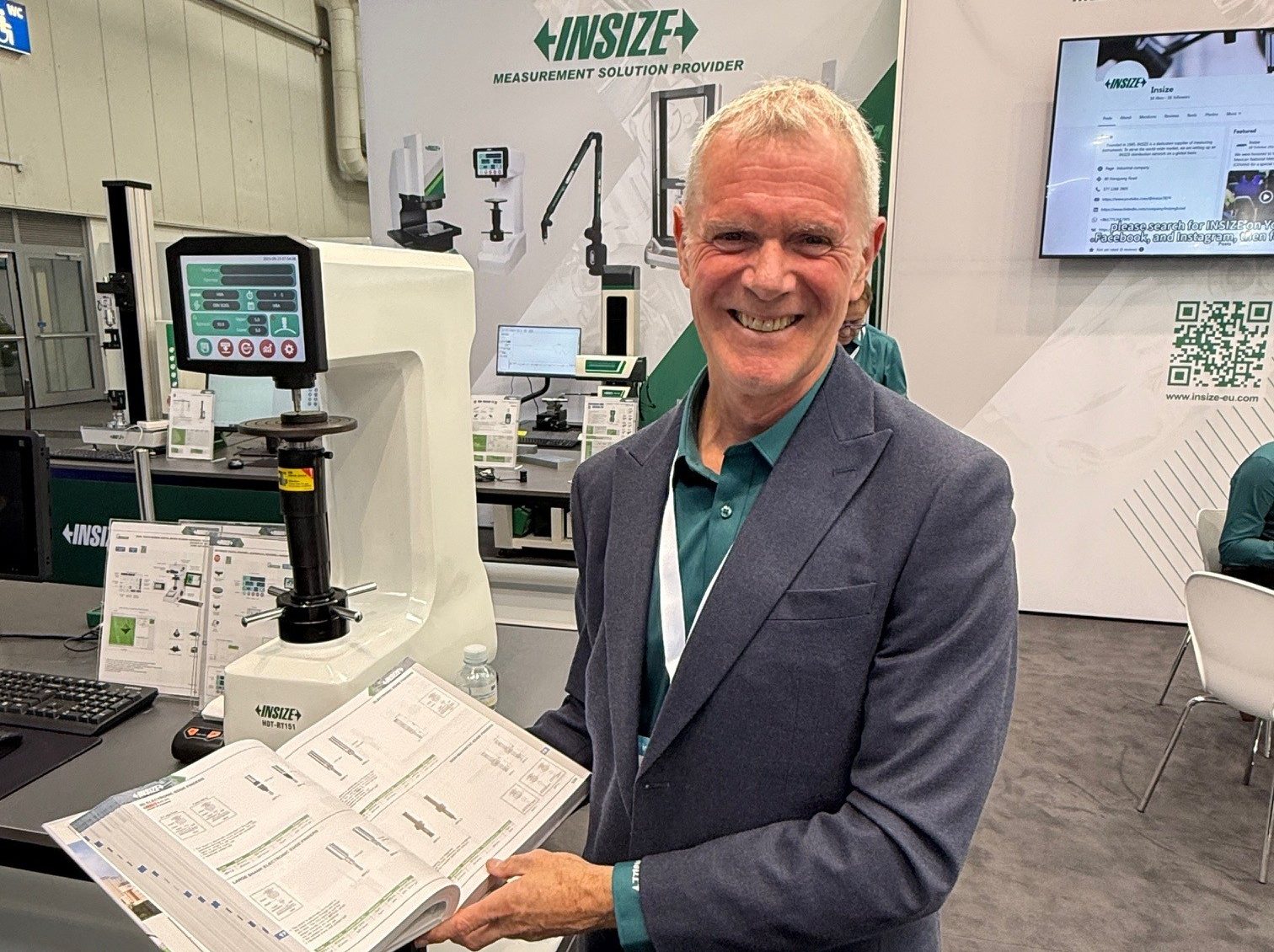

Like all technology segments, artificial intelligence (AI) is already bearing influence over metrology solutions like hardness testers. Insize, for example, a global manufacturer of measuring instruments with 16 subsidiaries worldwide and distributors in 120 countries, today uses AI in its R&D initiatives. Formed in 1995, the company’s ultra-modern headquarters in Suzhou, China, houses circa 200 R&D engineers, a team with 60+ patents to its name.

“Such high levels of ingenuity are necessary to support the vital role of hardness testing at every stage of production as quality processes evolve in line with key trends such as AI,” states John Hogan, Insize Sales Manager for the UK and Ireland. “Manufacturers currently rely on hardness testing to ensure components such as gears, crankshafts and bearings meet specification by confirming case hardening and heat-treatment integrity. It delivers direct correlation to the effectiveness of processes like quenching, tempering or nitriding.”

For those involving in R&D activities, perhaps at laboratories or universities, hardness testing offers a fast, quantitative way to evaluate new alloys, coatings or treatments. Another key role for this essential testing technology is compliance with industry standards, with many sectors requiring adherence to ISO 6508 (Rockwell), ISO 6507 (Vickers) or ISO 6506 (Brinell) for certification and traceability.

A question of scale

The preference for different hardness scales – Vickers (square-based diamond pyramid indenter), Rockwell (conical diamond or ball indenter), Brinell (hardened steel ball indenter) – is typically historic to the industry or company. Aerospace, for example, usually deploys the Vickers hardness scale. Whichever is preferable, most hardness testing is quick, taking approximately two minutes to obtain a result.

“As industries continue to innovate with lighter and more sustainable materials, hardness testing remains key to ensuring these advances deliver the required mechanical performance,” says John. “Across our advanced manufacturing sectors here in the UK, hardness verification is indispensable; valued for its speed, repeatability and correlation to key mechanical properties. From R&D to production and maintenance, it ensures every component performs as intended, safeguarding both your company’s reputation and compliance.”

Market’s widest portfolio

Founded in 1995, Insize has grown rapidly to be become a major manufacturer of measuring instruments with over 10,000 products in its portfolio. Covering all primary ISO hardness standards, the company’s website features more than 50 hardness testers (including portable testers) that extend from manual, through semi-automatic, to fully automatic systems with digital touchscreens. All models with digital interfaces offer automatic load control, data logging and SPC output for seamless quality tracking – as well as the ability to convert results across hardness scales.

With a UK subsidiary and support from long-standing agent, Cutwel, hardness testers represent around 10-15% of turnover at Insize UK, which also offers calibration services.

“Our testers are designed for precision, practicality and ease of use, with systems available for Brinell, Vickers, Rockwell, UCI, Shore (rubber and plastics) and Leeb (very large component) testing methods,” explains John. “They are cost-effective, perhaps half the price of products you would normally find in the UK, without any compromise in accuracy or reliability. Our most popular models include the HDT-RT151 – a high-resolution, affordable Rockwell tester – and the HDT-LP200 portable system, which can convert between scales for maximum flexibility. User-friendliness is assured with simple calibration, automatic dwell times and intuitive interfaces. All come with a one-year warranty.”

He adds: “I have over three decades of experience and knowledge in metrology industry, including a long background in sales and technical applications across two spells with Mahr and – put simply – I wouldn’t promote a product range that I didn’t believe in. Capital investment is tough right now for both manufacturers and R&D institutions due to several external factors. The market requires solutions that are high in precision and performance, but do not stretch the budget. Here at Insize, we feel we’ve struck the right balance with our high-quality yet cost-effective range of hardness testers.”