How AddQual is using metrology to rethink manufacturing qualification

In the world of high-stakes manufacturing – think aerospace, power generation and medical devices – there’s little room for error. Every component has to be perfect, every measurement exact. Yet the process of verifying and qualifying these parts can be…well, a bit of a nightmare. Scrap costs pile up. Production slows to a crawl. Launches get delayed. Sound familiar?

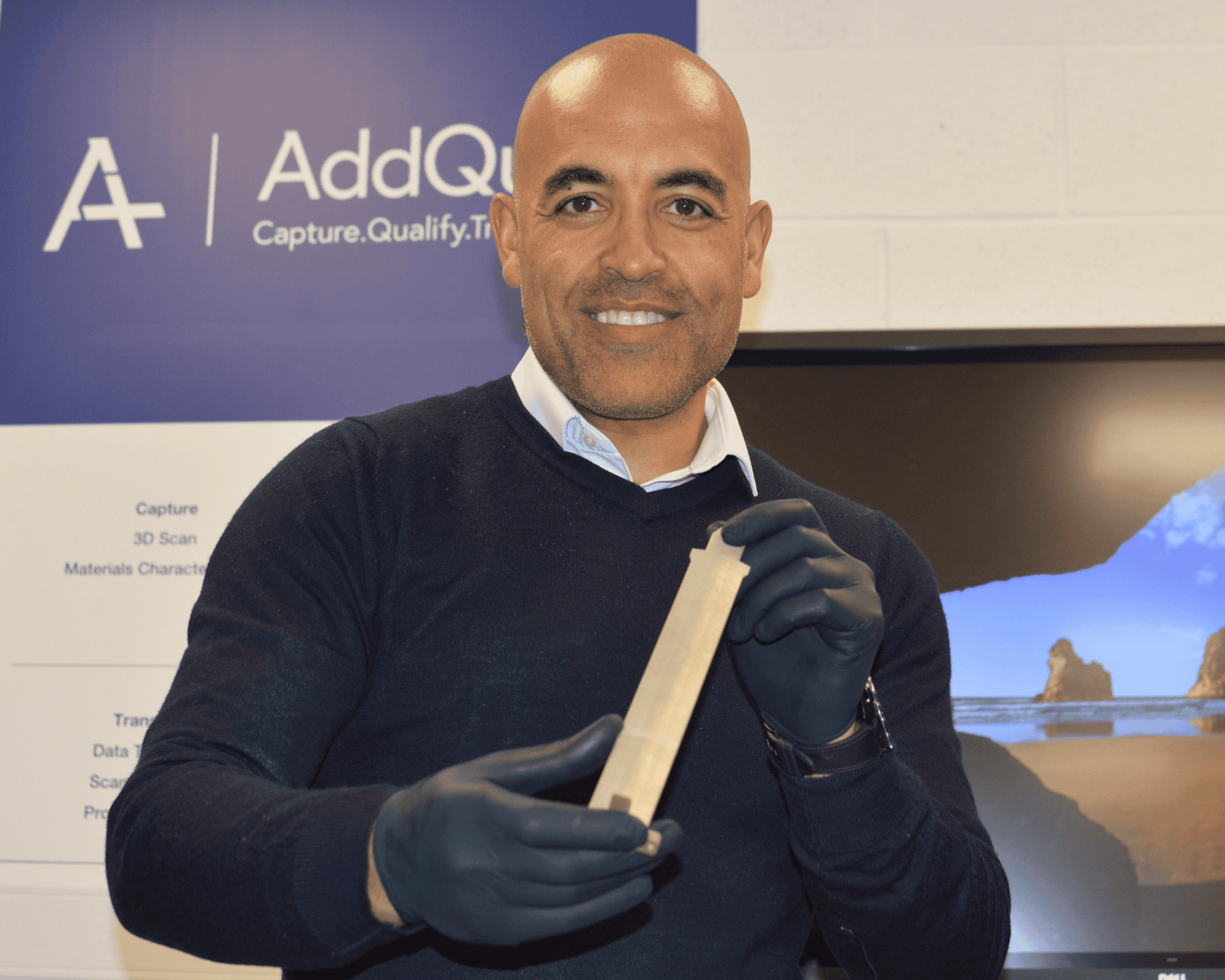

It’s a pain point that Ben Anderson knows all too well. “Personal pains,” he calls them. As the founder and Managing Director of AddQual, Ben Anderson set out to tackle the inefficiencies of traditional qualification head-on by putting metrology, the science of measurement, at the very heart of manufacturing quality.

“I saw it again and again,” he recalls. “Manufacturers were generating mountains of measurement data, but there was a massive gap between having the data and being able to make confident decisions from it. Everything felt slow, expensive and, frankly, prone to human error.”

Changing the game, one measurement at a time

AddQual isn’t just another quality control firm. It’s a metrology-driven mission with a clear focus: helping manufacturers of safety-critical components qualify parts quickly, consistently and with full confidence.

Its suite of services is designed to cut through the chaos that plagues traditional quality assurance. From supporting component qualification to optimising production inspection and guiding continuous improvement investigations, AddQual says it’s reshaping how businesses think about quality.

One of the company’s core offerings is its component qualification service, handling metrology data capture and reporting for everything from tiny 2mm³ parts to whopping 2m³ structures, across all manner of materials.

“OEMs and MROs often come to us with incomplete or unclear inspection requirements,” explains Ben Anderson. “It leads to delays, confusion, and costly rework. We work alongside them to fine-tune and clarify those requirements, making sure they’re not just ticking boxes but actually aligning with industry standards.”

In practice, that means creating dimensional metrology systems that are integrated into the customer’s workflow. It’s metrology done with purpose and precision.

From data deluge to clarity

Production inspection is another space where AddQual makes a big difference. Today’s manufacturers are swamped with data, but not all of it’s useful. In fact, too much of it can be paralysing.

“Companies are drowning in spreadsheets and reports, yet starved of insight. We help them break out of that doom loop by combining metrology expertise with clever fixturing, automation and data management software.”

The result? Processes that are less reliant on gut instinct and more informed by structured, traceable data. Engineers can stop second-guessing and start improving, with speed and certainty.

Investigating the issues, properly

And then there’s the dreaded ‘what went wrong’ moment. When inconsistencies crop up or components fail, manufacturers need reliable answers fast.

“Paper-based systems and manual decision-making just don’t cut it anymore,” says Ben Anderson. “Too many critical decisions still hinge on subjective judgement. That’s risky.”

AddQual’s continuous improvement investigation services are built around structured metrology data, collected using advanced 3D structured light techniques, CMMs, callipers, micrometres and other inspection tools. Combined with NADCAP-accredited processes, this data is trustworthy enough to support real root cause analysis and lasting improvement.

Breaking down the silos

Another big headache in manufacturing is data fragmentation. Different systems store different data in different formats. It slows everything down, introduces human error and makes integration a nightmare.

AddQual tackles that problem head-on. The companys’ platform transforms raw measurement data into structured, traceable insights. That means faster decision-making and less time spent trying to make sense of conflicting reports.

“Our whole aim,” summarises Ben Anderson, “is to automate quality control decision-making. We want to remove variability, improve responsiveness and let manufacturers focus on making great products, not just measuring them.”

Metrology, with a mission

By placing structured metrology and autonomous inspection at the centre of its strategy, AddQual has carved out a unique role in the manufacturing world. It’s not just about better measurements, it’s about better outcomes.

For businesses facing the pressure of compliance, consistency and cost, AddQual offers more than just a service. It offers peace of mind; because in an industry where there’s no room for guesswork, precision isn’t a luxury, it’s a necessity.