How Armour Edge used 3D scanning technology from MSL to reinvent blade protection

Armour Edge offers a cutting-edge solution designed to protect wind turbine blades from erosion. The company’s system consists of ultra-tough, custom-fitted erosion shields made from a specialised thermoplastic material. This solution not only minimises maintenance costs but also ensures that turbine blades maintain optimal aerodynamic performance, reducing downtime and increasing energy production.

Traditional solutions such as paints and tapes often require replacement every 2 to 5 years. In contrast, Armour Edge LEP shields are engineered to last over 15 years, providing a long-term, cost-effective solution. Each shield is custom-designed to fit the specific size and type of blade, ensuring a precise fit and optimal protection. Easy to install and built for lasting performance, they offer reliable defence for the full operational life of the blade.

With proven success in European offshore wind farms and projects across the US, India and Australia, Armour Edge continues to deliver reliable, high-performance protection for both onshore and offshore wind energy markets.

Objective

Armour Edge sought to improve the performance and longevity of wind turbine blades, which are prone to erosion from environmental factors like rain, ice, and dust. Its goal was to develop a custom-fit protective solution that offers a significantly longer lifespan than existing products in the market, as well as a simpler installation process.

The primary ambition was to reduce downtime and maintenance costs by providing a product that could withstand extreme environmental conditions and require minimal future intervention. Wind turbines are crucial to low carbon energy generation, but blades face degradation due to harsh conditions, especially offshore. Armour Edge uses 3D scanning as part of its design and manufacture process.

The challenge

Wind turbine blades come in many shapes and sizes, depending on the manufacturer, model and specific site conditions. The primary challenge for Armour Edge was to create a product that would fit each size and type of blade’s unique geometry and withstand the challenging conditions, while minimising downtime and maintenance costs.

A one-size-fits-all solution was not viable for providing optimal protection. Additionally, the blades are often located in remote or difficult-to-access locations, such as offshore wind farms, which adds to the challenge of conducting maintenance and repairs.

Armour Edge needed a way to accurately capture the geometry of each size and type of blade to ensure their protective solutions fitted perfectly and offered maximum durability.

The application

Wind turbines play a vital role in low-carbon energy generation, yet their blades are prone to degradation from harsh environmental conditions, particularly offshore. Armour Edge integrates 3D scanning into its design and manufacturing process to address this challenge effectively.

3D scanning is employed to capture the precise geometry of the leading edge of wind turbine blades to create custom-fitted LEP shields. This allows Armour Edge to generate detailed CAD designs tailored to the specific blade type and size.

The process involves:

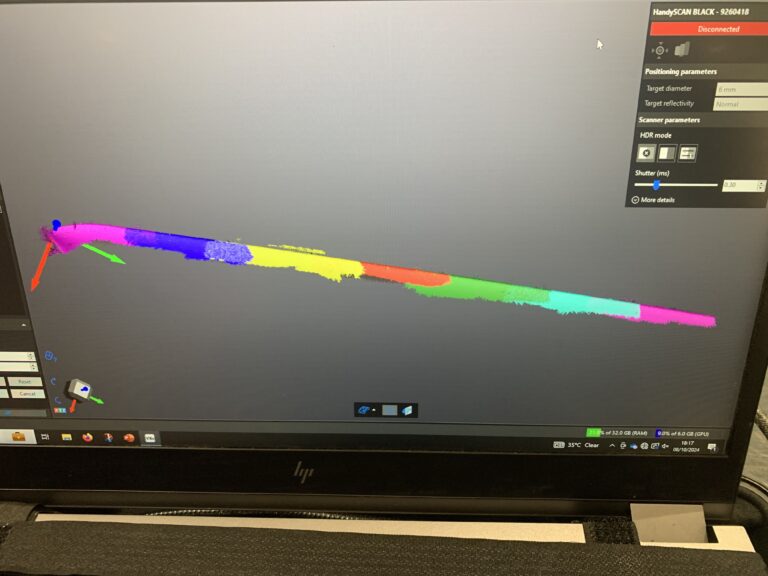

- Capturing data: The Creaform HandySCAN Black from Measurement Solutions Ltd (MSL) is used to collect detailed measurements of the turbine blade’s leading edge, ensuring the unique shape and structure of each blade are accurately documented.

- Custom design: The scanned data is used to create custom thermoforming tools that produce erosion shields precisely matching the scanned geometry.

- Precise fit: This level of precision ensures that the Armour Edge shields fit seamlessly, preserving the aerodynamic efficiency of the blades, which is critical for maximising energy production

By utilising 3D scanning, Armour Edge ensures a high level of customisation and quality control in its erosion protection solutions.

The solution

Armour Edge turned to MSL and the Creaform 3D scanning technology to address the challenges faced in custom-fitting the company’s protection system. Using the HandySCAN Black, Armour Edge could capture precise geometry of each size and type of wind turbine blade, ensuring a tailored fit for their protection system.

The scanning process allows Armour Edge’s team to generate tooling and manufacture parts that are specifically designed for each size and type of blade, ensuring maximum durability and ease of installation.

Initially, Armour Edge leased a scanner to test its effectiveness, but after trialling the solution and witnessing the substantial benefits, the company invested in purchasing its own equipment. The portability of the HandySCAN Black allows the team to conduct scans on-site around the world, including remote locations such as offshore wind farms, using rope access techniques.

This streamlined the process and reduced the need for external scanning services. The scanning technology also streamlined production by building an IP library for different blade makes and models, reducing the time, associated cost and effort involved for future installations.

HandySCAN 3D Black

The Creaform HandySCAN 3D Black scanner has been optimised to meet the needs of design, manufacturing and metrology professionals looking for effective and reliable ways to acquire accurate 3D measurements of physical objects anywhere.

Benefits

Armour Edge realises several key benefits by incorporating 3D scanning into its processes for designing leading-edge protection (LEP) for wind turbine blades:

- Custom-fit solution: The 3D scanning process enabled Armour Edge to create a tailored protection system for each wind turbine blade, improving ease and consistency of installation compared to generic tapes and coatings.

- Increased longevity: While traditional methods like coatings and tapes can require reapplication every 2 to 5 years, Armour Edge’s system offers a lifetime solution, potentially lasting over 15 years.

- Reduced Downtime: By fitting a durable, long-lasting protective system, wind turbines experience less downtime, which is crucial for maximising energy generation and minimising maintenance costs.

- Portability and flexibility: The HandySCAN Black’s portability allowed the Armour Edge team to perform scans in the field, reducing lead times and eliminating the need for third-party scanning services.

- Improved aerodynamics: With 3D scanning, Armour Edge can design shields that seamlessly integrate with the blade’s surface, minimising drag and preserving the blade’s aerodynamic profile. This results in better energy production and overall performance for wind farms.

- Efficiency in manufacturing: By using scanned data to create CAD models and precise thermoforming tools, Armour Edge can streamline the manufacturing process. This ensures that each shield fits perfectly the first time, reducing production errors and waste.

- Speed: The scanning process and easy installation of the shields allow for faster application compared with traditional methods.

- Scalability: The IP library developed through scanning allows Armour Edge to reuse tooling for future installations, further reducing costs and lead times.

- Return on investment (ROI): The scanner paid for itself within the first year, eliminating the costs of leasing and external scanning services and allowing Armour Edge to fully integrate the technology into its in-house processes.

Overall, 3D scanning enhances the accuracy, efficiency, and performance of Armour Edge’s solutions, giving it a competitive edge in the wind energy sector.

The results

Armour Edge successfully developed and implemented a system that has outperformed traditional protection methods. The solution has proven to last significantly longer, even in harsh offshore environments where turbine blades are exposed to increased erosion from particulates.

The company reported immediate ROI from the adoption of the HandySCAN 3D scanner. It paid for itself after the first year, reducing leasing costs, labour and time previously associated with third-party services, whilst also ensuring availability.

The custom-fit design, enabled by the Creaform scanning technology provided by MSL, has reduced installation time and costs while providing a superior level of protection. As a result, Armour Edge has positioned itself as a leader in wind turbine blade protection, offering a product that is not only more durable but also more efficient to install.

Final outcome

By adopting MSL’s 3D scanning technology, Armour Edge has been able to transform wind turbine blade protection. The company’s solution has become a unique selling point in the market, with no competitors able to offer the same level of customisation. The process of using 3D scans to create custom-fit parts has given Armour Edge a significant competitive advantage, positioning it as a leader in the industry.

The company’s solution not only improves blade longevity but also reduces the overall cost of wind turbine maintenance, particularly in offshore installations where access is limited and expensive.

With continued collaboration with MSL, Armour Edge aims to enhance its products and processes further, setting new standards in the wind turbine industry and serving as a testament to the power of innovative technology in solving industry challenges.

Says Will Howell, Operations Director at Armour Edge: “We couldn’t have developed Armour Edge without the precise scanning capabilities provided by MSL’s 3D scanning technology. It was a game-changer for us, allowing us to create a product that fits perfectly on every blade and lasts longer than anything else in the market. The investment in our scanner has paid for itself multiple times over, and we can confidently say we wouldn’t be where we are today without it.”