Measured to perfection: Granite machining refined

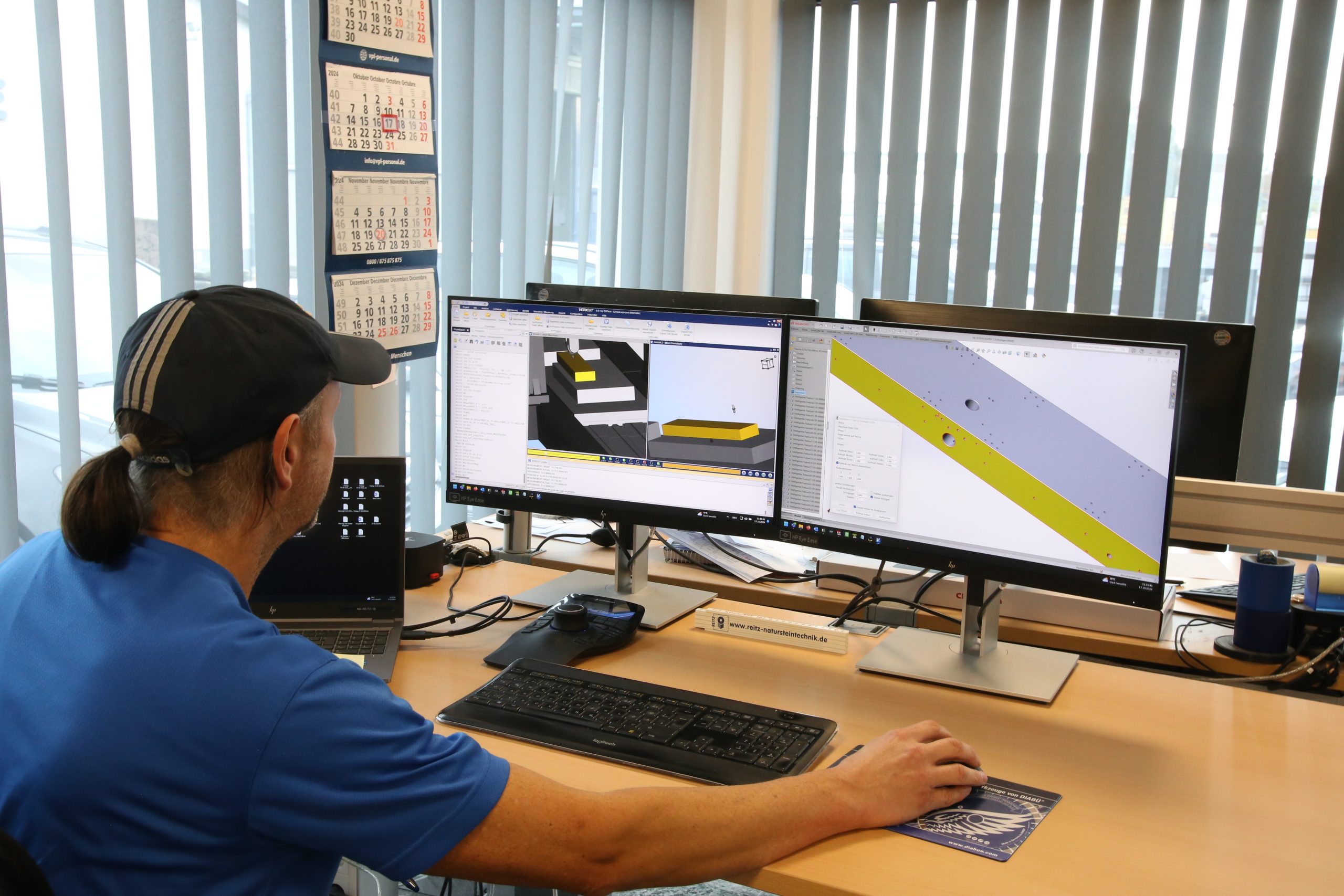

Reitz Natursteintechnik KG specialises in the design and manufacture of highly precise machine components made from granite. To ensure efficient and safe processing, the company relies on Vericut simulation software. This supports reliable production and reduces the workload for employees.

The company’s history dates to 1946, when Herrmann Reitz began quarrying stone in Asslar. In 1958, his son Friedel Reitz expanded into gravestone production. The third generation, Egbert Reitz, continued this until 1987, when the business shifted to making granite surface plates. This change led to the founding of E. Reitz Natursteintechnik e.K. in 1986. Today, Christopher Reitz leads the company and focuses on meeting modern customer needs.

He says: “Today’s components combine million-year-old stone with advanced technology. For over 35 years, we’ve been manufacturing precision granite parts and offering everything from system assembly to custom solutions, all from a single source.”

Based in Asslar, Hesse, Reitz employs around 140 people. Its clients work in sectors including semiconductors, optics, engineering, automation, metrology, printing and medical technology.

Why granite matters

“We’ve been working with natural hard stone for over 60 years,” says Christopher Reitz. “It’s a tradition we take seriously.”

In mechanical engineering, especially machine tool building, precision is essential. The machine bed is key to performance and granite offers distinct advantages.

“Granite has qualities that neither steel nor mineral casting can match. Its stability, resistance to temperature changes, vibration damping and guidance accuracy make it ideal for precision machinery.”

The material sees widespread use in test stands, measuring systems and co-ordinate measuring machines. Typical components include surface plates, tables and frames.

Building and milling in-house

Reitz sources granite mainly from South Africa, Spain, France and Austria. It arrives as slabs or raw blocks and is processed internally. Workpieces range in size from 250 x 250 mm up to 13 m. The largest to date measured 13 x 1.5 x 1 m and weighed about 65 tonnes. To handle workpieces of this magnitude, in-house CNC machine tools are put to use: four gantry-type milling machines and two 5-axis gantry machines, all with Siemens 840D control systems.

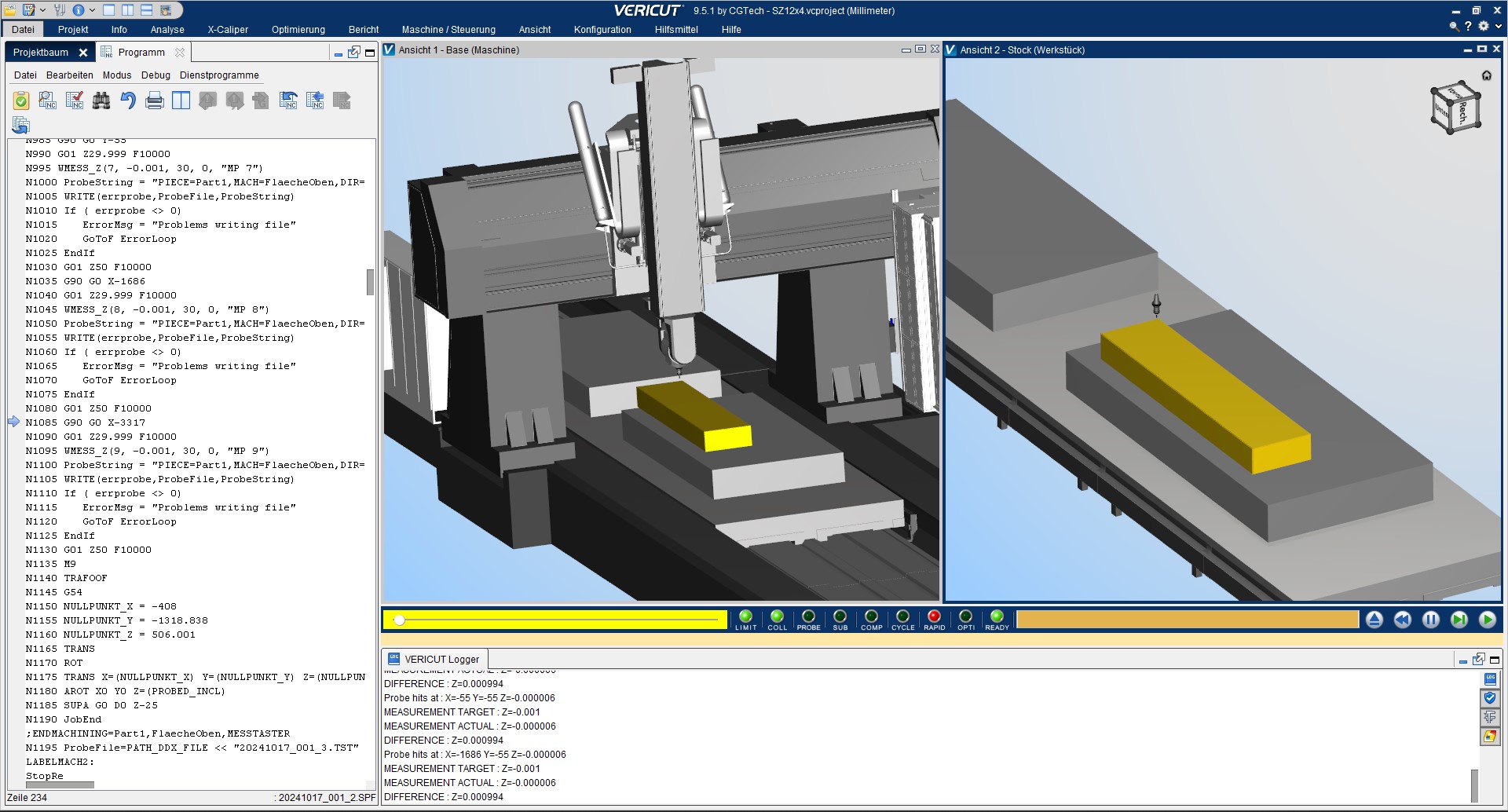

For precise, safe processing, the company uses Vericut simulation software. “Granite surfaces are never perfectly flat,” says Christopher Reitz. “We developed a process using Vericut that eliminates tool collision risks.”

Stephan Meurisse, Marketing Manager at Vericut Deutschland, adds: “Downtime, broken tools, collisions, long set-up times, and material waste cost time and money. Vericut helps avoid these problems.”

Collision avoidance and reliability

Vericut has specialised in NC simulation and verification for CNC machining, additive and hybrid manufacturing since 1988.

“Vericut removes the need for manual set up, protects our machines and saves operator time,” says René Maschlanka, responsible for sales and project management at Reitz.

Precise and efficient workflow

Granite blocks often arrive with an excess of 3 to 5 mm. They are machined to a flatness of 20 to 5 microns. Due to granite’s hardness (Mohs 6 to 8), only 0.1 mm can be removed in each cut.

Says René Maschlanka: “After inspection, the operator selects a measurement pattern. This produces two automatic programs in the CAM system. One determines the block’s position, the other maps the surface using probing cycles.”

Probing takes machine time, so it’s used efficiently. The data is then converted to NC code and simulated in Vericut before machining begins.

“The measurements show the real surface condition,” explains Stephan Meurisse. “From that, a machining program is generated and simulated in Vericut before being run.”

Once the cuboid is machined, it’s drilled for rails, spindles, sensors and other parts. Threaded inserts are glued in before the component moves to the climate-controlled precision lab for final machining.

“Final programs are also validated in Vericut,” adds René Maschlanka.

Digital twin simplifies work

“We use a special CAM system for granite,” reveals René Maschlanka. “We built our own interface with Vericut. It accurately captures the workpiece’s position and shape, letting us simulate all steps without manual set up.”

This helps identify unnecessary movements, clamping mistakes, and wrong tool use before they cause problems.

“Now our programmers and operators are more confident. They know their programs are safe.”

Some jobs take over 40 hours. In the past, operators had to monitor them continuously. Now they simulate on a PC, start the machine and only check in when needed.

“The Vericut Reviewer helps us decide when that is appropriate,” says Christopher Reitz.

Supporting operators with Vericut Reviewer

The Vericut Reviewer allows users to view and interact with simulations on any Windows PC or tablet. It builds trust in the process.

“Operators and engineers can check the simulation and confirm accuracy before running the job,” says Stephan Meurisse.

René Maschlanka adds: “Our team likes the Reviewer. It shows the complete sequence, highlights critical points, and supports planning tasks like tool selection and clamping.”

With Vericut, programming errors, tool breakage and collisions are no longer a concern at Reitz Natursteintechnik KG.

“Vericut is a great tool – it’s easy to use, prevents errors and gives our team peace of mind,” says Christopher Reitz.

Stephan Meurisse concludes: “This project was an exciting challenge for us. We usually work with metal, not granite. It proves Vericut can handle even multi-ton granite blocks safely and efficiently.”