Measuring system for EV and the Aerospace Industry

Brandauer, based in Birmingham is a leading producer of precision stamped parts. Founded in Birmingham over 150 years ago, this family run enterprise has real manufacturing pedigree, having won a Queen’s Award for international trade. Committed to leading edge innovation, they are the only UK supplier of the EloPin press-fit, developed by TBS Sorig.

As a manufacturer of bespoke metal stamped components, they need to ensure that they will meet the demands of the application. In this case to ensure that the press fit Elo pins used in critical connectors not only have dimensional accuracy but will meet the pull-out force requirements to ensure reliability.

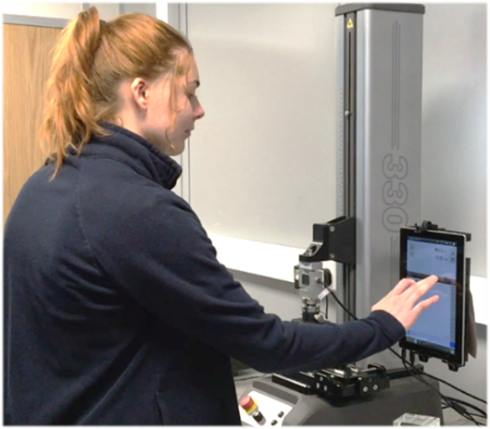

The system chosen, which is suited to safety critical applications, the versatile, automated, Starrett L2 force measurement system (FMS) is relied upon for quality control in EloPin production.

Force Measurement Solution Solves the Problem

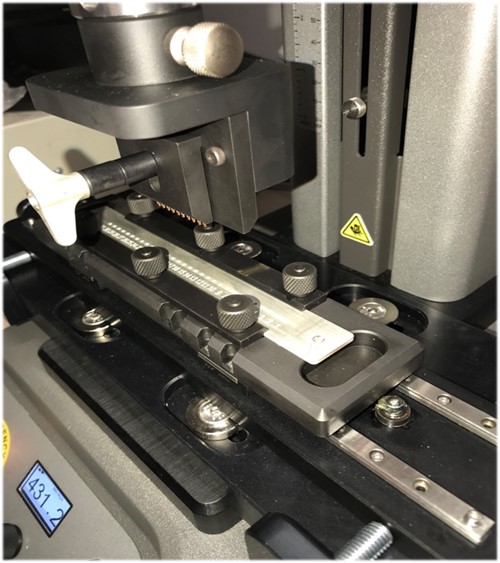

The EloPin press-fit poses a significant measurement challenge. The size of the pins and the pin-hole alignment during insertion, requires precise alignment and complete automation when implemented into a production environment. The insertion and extraction force are measured using a motorised mechanical frame, with load cell and controlling software attached, Starrett manufacture many different variants and in this case the FMS frame with L2 software matched the strict drawing parameters. Optimax designed and built a specialised jig for the Starrett L2 FMS, allowing various sizes of EloPin to be loaded and the measurements completed without out operator alignment. It was this comprehensive, end-to-end solution that attracted Brandauer to Optimax.

Significant impact on cycle times

The robustness and versatility of the L2 Starrett has had significant impact on cycle times as well as satisfying Brandauer’s commitment to the highest level of quality control. The device is intuitive to use and fully programable, allowing for use by staff not trained in inspection. An attractive feature for Brandauer who hold, as a core operating principle, that press shop operatives share ownership for the product quality coming off the press tools. The robust FMS L2 Starrett force machine is therefore able to run throughout the day, testing every reel of 20,000 pins stamped. By simply changing the jig, Brandauer are also able to measure a second, American press-fit solution and a range of products for their Chinese clients.