Mitutoyo Supports Skar Precision Mouldings with Advanced Metrology Solutions

When investing in capital equipment, businesses consider not only the quality of the product but also the level of customer support provided by the supplier. Mitutoyo, renowned for its precision measurement solutions, excels in both areas—offering industry-leading metrology equipment alongside comprehensive customer service.

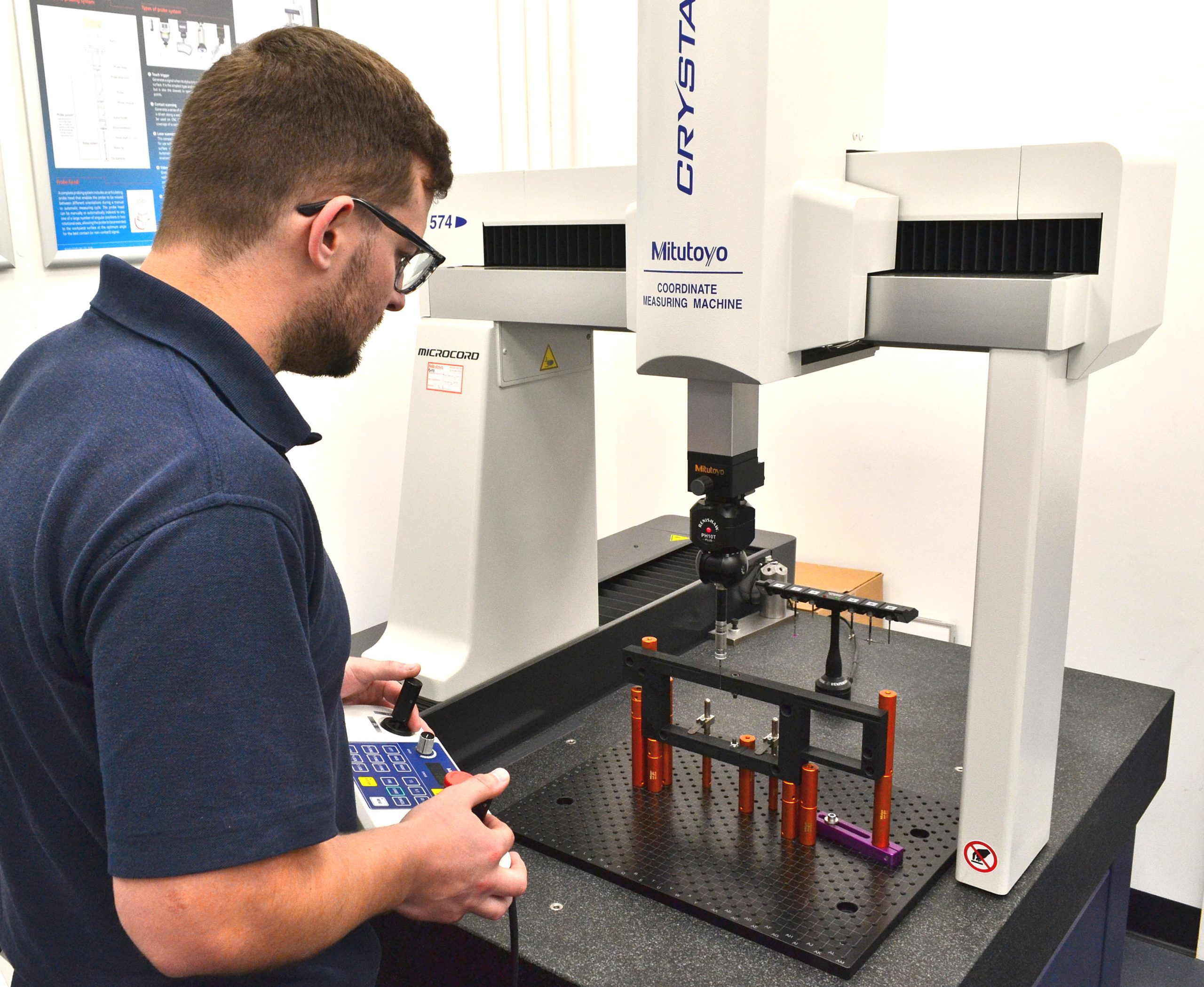

This commitment was recently demonstrated in Mitutoyo UK’s support of Skar Precision Mouldings, one of the UK’s largest injection moulding specialists. As Skar expanded its capabilities with the installation of a high-accuracy CRYSTA-Apex S Coordinate Measuring Machine (CMM), Mitutoyo provided expert assistance before, during, and after the setup—ensuring seamless integration into Skar’s stringent quality assurance processes.

Founded in 1969, Skar Precision Mouldings has grown into one of the UK’s leading injection moulding specialists. With over five decades of expertise, the company offers comprehensive knowledge of the plastic injection moulding process, providing guidance on design for manufacturing, efficient production, and assembly.

To meet increasing demand, Skar operates 35 high-performance moulding machines, ranging from 22 to 450 tonnes, with a maximum shot weight of 2.4kg. Production runs 24 hours a day, five days a week, ensuring efficiency and reliability.

Serving highly regulated industries, Skar enforces a rigorous quality assurance system, integrating strict monitoring and control measures across all operations. A key focus area is the precision injection moulding of components for medical equipment, earning the company approved supplier status with some of the world’s largest medical manufacturers.

Recently, the need for high-precision inspection and detailed reporting for complex components—produced for a multinational medical analysis equipment manufacturer—led Skar to search for a highly accurate CMM. After evaluating several leading metrology providers, the company selected Mitutoyo UK’s CRYSTA-Apex S 574, a CNC CMM with an X,Y,Z capacity of 500mm x 700mm x 400mm and a maximum permissible length measurement error of E0, MPE = (1.7+3L/1000) μm.

With Skar’s new temperature-controlled inspection facility still under construction at the time of delivery, the company turned to Mitutoyo’s extensive customer support services.

Paul Chaplin, Quality Engineer and CMM Programmer at Skar, explained:

“As one of the UK’s longest-established injection moulding specialists, we serve customers across the UK, Europe, and beyond. Our commitment to precision and quality is reflected in our ISO 9001, ISO 14001, and ISO 45001 certifications, as well as our comprehensive quality management system, which includes full material batch traceability, sample inspection reports, process capability studies, and detailed inspection documentation.

“When our new inspection facility was delayed, Mitutoyo’s expertise proved invaluable. Their Measurement Services Department provided efficient subcontract inspection, ensuring our critical components were measured and delivered on time with comprehensive reports. Once our CMM was installed, Mitutoyo supplied essential part programs and provided in-depth training, allowing us to immediately integrate the machine into our processes. On the rare occasion that we need assistance, Mitutoyo’s support team is always readily available.”

Beyond supplying cutting-edge measurement equipment, Mitutoyo is a global leader in precision metrology solutions, offering an extensive range of products, from micrometers and calipers to hardness testers and 3D Coordinate Measuring Machines. Their CMMs are available in a variety of sizes and accuracy levels to meet the demands of nearly any precision measuring application.

Mitutoyo’s dedication to customer support extends to businesses across diverse industries. The company’s Measurement Services Department ensures that when in-house QA inspection capacity is exceeded, clients can rely on timely and accurate external metrology solutions.