Optical metrology: Seeing is believing

Measurement & Manufacturing speaks exclusively with Optimax about the advance of optical metrology and how a new ‘holy grail’ innovation is about to disrupt the quality control landscape.

The market is not short of metrology equipment suppliers, so providing some level of differentiation is paramount, a point not lost on Midlands-based Optimax. From its state-of-the-art applications lab in Leicestershire, which houses metrology equipment worth over £1 million, visitors tend to leave with a very different perception of what’s actually possible regarding automated optical inspection and measurement.

“The light bulb moment is realising the potential of transitioning from 2D, 2.5D or structured CMM-defined point measurement, to the freeform world of optical metrology where we’re collecting millions of high-resolution data points every second,” explains Pete Clements, Managing Director and Head of the UKAS Laboratory at Optimax Production Metrology & Inspection Services. “Manufacturers can then decide what improvements to drive from that data. It’s an extremely flexible, fast and information-rich process.”

Solutions not products

Identifying solutions rather than products – by comparing methods and technologies – is the way Optimax adds value for customers, delivering both return-on-investment (ROI) and long-term operational gains. As a ‘house of brands’ with products calibrated to UKAS standards, the company’s impartiality is a crucial ingredient in helping manufacturers achieve their ambitions. Optimax underpins its approach by applying a measurement uncertainty budget so customers can understand the solution’s performance potential set against the real-world application.

Notably, close alignment with the manufacturing sector is placing new demands on metrology, with automation and artificial intelligence (AI) proving pertinent examples. Optimax recently signed an exclusive agreement for the metrology market with robotics manufacturer Doosan, providing true in-line inspection and metrology with automated product load/unload capabilities and closed-loop feedback to machine tools.

“We think we’re pretty early on the curve with solutions of this type,” says Pete Clements. “Moreover, because optical metrology offers such high resolution, it’s possible to perceive tiny changes in surface topology that indicate cutting tool wear long before dimensional errors become evident.”

The smart set

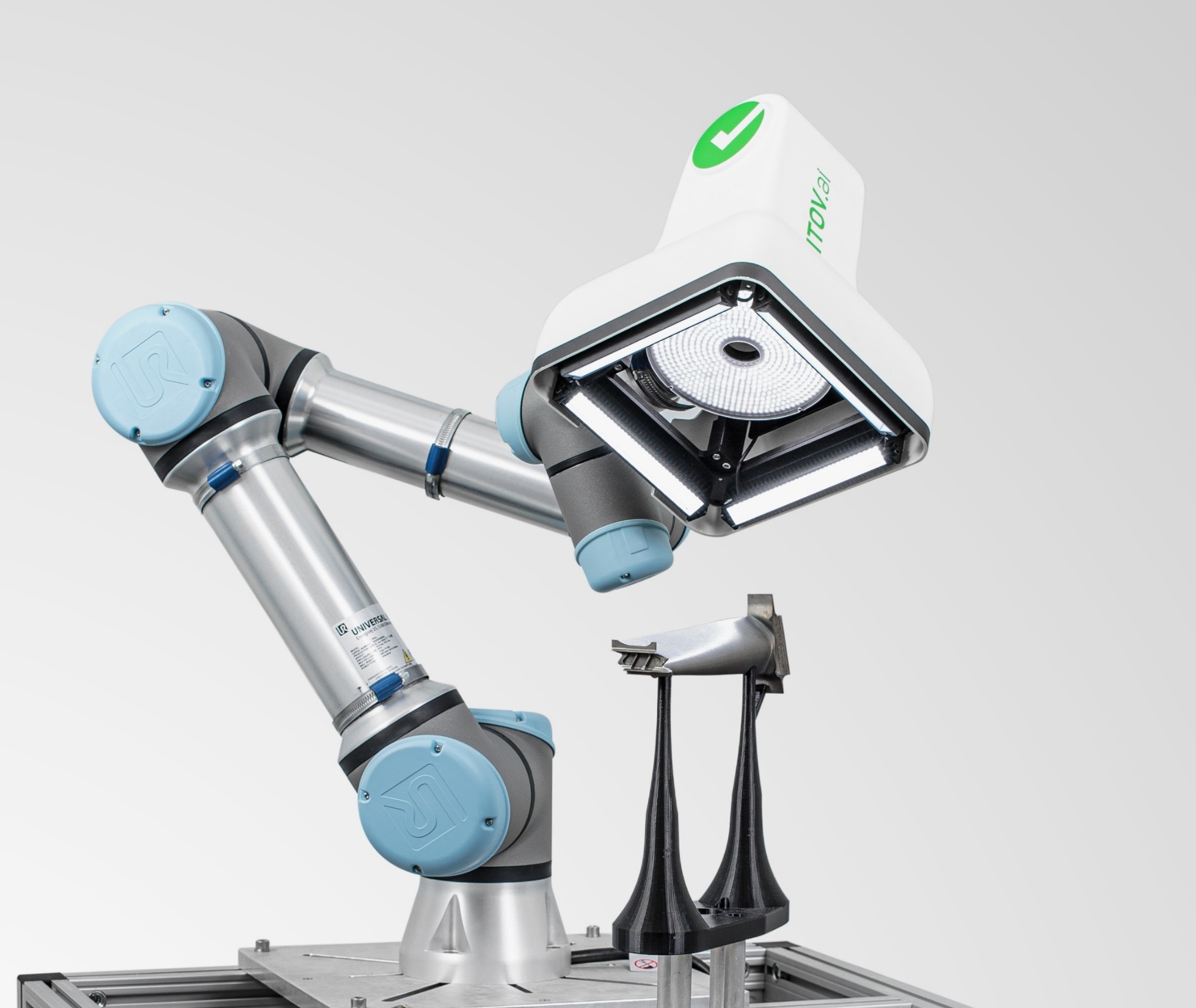

Optimax is about to launch an AI-based system that not only represents a market-first, but also the proverbial ‘holy grail’ of quality control. Users simply import a solid model that prompts the system’s robot (with mounted AI multisensory head) to inspect the part, find defect attributes – such as a scratch, crack or a dimensional discrepancy – before logging and measuring the defects (via a sensor change). The ability to inspect surfaces and measure dimensions automatically from the CAD model without long-haul programming is now here: automated lighting control with deep learning, 2D/3D imaging and intelligent robotic planning in a single platform.

The system, which for reference is the Kitov Core (and Core Plus) AI-based smart visual inspection system, can inspect defects less than 1 thousandth of an inch and provide quantification to nanometres dependant on sensor and surface attributes such as topography and finish. It can also provide insight for production process control via closed-loop feedback to machine tools, subsequently preventing defects prior to manufacture. Further system attributes include 6-axis robot movement, plus an optional 7th axis (rotary stage) that provides critical ‘line of sight’ into even the most complex geometry.

“The AI system learns from variables of good products and builds its AI model. Everyone wants to see tangible outcomes of AI in manufacturing, and we definitely have one here.”

Optical metrology is coming of age and UK manufacturers are getting on board, as reflected by the 17% growth Optimax witnessed in 2024.

“More manufacturers are trusting us to identify automated optical metrology solutions that save them money,” states Pete Clements. “The use of metrology tools to enhance or accelerate manufacturing processes is beginning to infiltrate the mindset of precision engineers. They can combine several processes in a single system, inspecting and measuring geometry, roughness, waviness, cutting tool wear, bores, edge break and more. Yes, it requires capital investment, but less than buying a separate CMM, roundness tester, roughness tester and shadowgraph. What’s more, the robot eliminates the need for operators, allowing the transfer of human resources into higher quality roles.”

Ahead of schedule

Alongside its solutions-based approach, Optimax can put forward a further market differentiator: its UKAS laboratory status.

“We understood from the beginning that without credible accreditation it would be difficult to nurture customer confidence. Our lab carries a number of schedules under the ISO17025 umbrella.”

The lab was the UK’s first to gain UKAS accreditation in accordance with ISO10360-7 (CMM with optical probe). More recently it achieved another UK first: UKAS accreditation for optical shaft measurement.

“We know the value it adds for customers if they can use an optical metrology product that’s traceable to a globally recognised standard,” he concludes. “It helps more manufacturers understand that optical metrology – with its clear advantages of data density and contactless operation – is the route to high-speed, high-resolution inspection and measurement.”