Optimax teams up with cobot specialist to boost automated inspection

The pursuit of excellence in high-value manufacturing has always been integrated measurement and visual inspection, directly within the production process. The goal is to eliminate the need for post-process inspections and the offline allocation of costly, specialised resources. By embedding these critical functions into production workflows, manufacturers can achieve greater efficiency, higher precision, reduced lead times and lower cost. With these goals in mind, Optimax is teaming up with Doosan Robotics to enable the integration of measurement solutions with Doosan collaborative robots (cobots).

Traditional approaches to the challenge, which rely on manual part handling and inspection, not only delay output but also add significant overhead costs. Additionally, these processes introduce potential risks, especially when working with delicate, precision-engineered components, where mishandling or repeated handling can lead to damage or compromise quality.

A solution to this problem is an exclusive agreement between Optimax and Doosan Robotics, enabling the integration of measurement solutions with Doosan cobots. According to Optimax, the partnership offers new capability in the UK: integrating a wide range optical sensors to deliver automated, high-resolution, repeatable and traceable measurements, even in demanding production environments.

Three product ranges

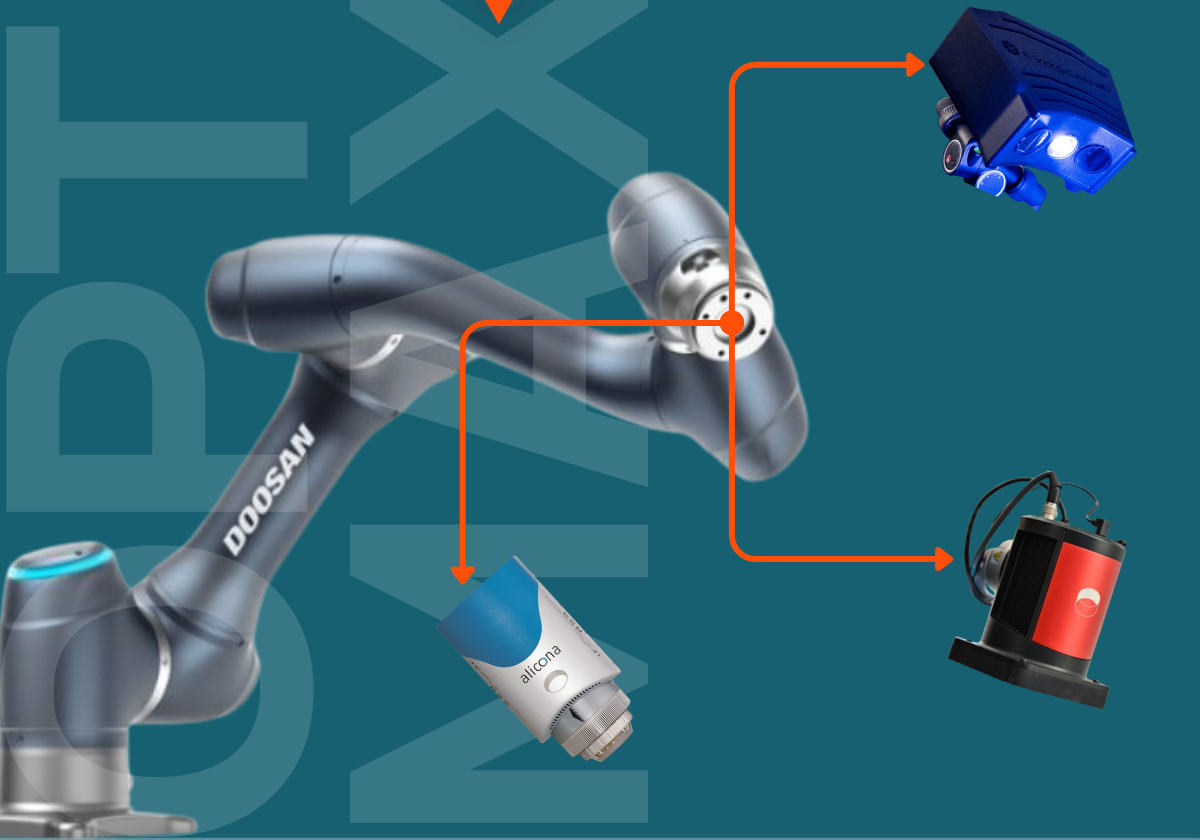

There are three main product ranges that can be incorporated and integrated by Optimax with the Doosan cobots: Evixscan 3D scanners; Bruker Alicona 3D metrology systems; and Inspekto AI-guided visual inspection systems.

Evixscan 3D scanners are known for their precision and versatility, catering to various industrial applications like reverse engineering, quality control and rapid prototyping. The portfolio includes models like the Optima+ M, designed for medium-sized objects with fast scanning times and high accuracy, and the Quadro+, which offers dual scanning ranges for both small and large objects, enhancing flexibility in manufacturing environments. These scanners use structured light technology and are designed for integration with automation systems like robotic arms and cobots, making them well-suited for modern Industry 4.0 production lines.

Bruker Alicona 3D metrology systems bring traceable optical 3D measurement to the manufacturing arena. Among the range of products available is the R25 sensor, which can be integrated into a production line. It delivers high-resolution, repeatable, traceable results when measuring surface characteristics in the micron or sub-micron range. Standardised interfaces (e.g. QDAS) support easy and quick integration into production, allowing comparable measurements. In combination with a collaborative six-axis robot, the solution supports fr flexible quality assurance and the measurement of microstructures on large components.

The Inspekto AI guided visual inspection system is both easy to use and integrate into production set-ups, either inline or near production. The S70 is completely different in its approach, offering the best of both worlds with its human-like flexibility, alongside machine accuracy, repeatability and reliability. The instrument is free standing or can mount to a cobot.

Metrology cobot

The Doosan M 1013 is chosen as the most suitable for metrology applications with its payload of 10 kg, reach of 1,300 mm and high repeatability. If the requirement varies from the standard, other models in the M series are available. These six-axis robots allow easy positioning of either the measurement sensor over the part, or the part to be measured under the sensor, providing complete flexibility.

Collaborating with the customer, according to requirements, Optimax will create a complete, integrated and easy to use solution. Furthermore, the company will install the system, train the users and provide aftersales support. Optimax can also perform calibration on a regular basis to ensure that the system meets the required standards.