Powering precision for the EV future

Tim Thorburn, Managing Director of Craftsman Tools, explains how the I4M programme, part of UKRI’s Strength in Places Fund and delivered by the National Physical Laboratory (NPL), enabled his team to rethink and refine a critical component of EV production: workholding for splined parts.

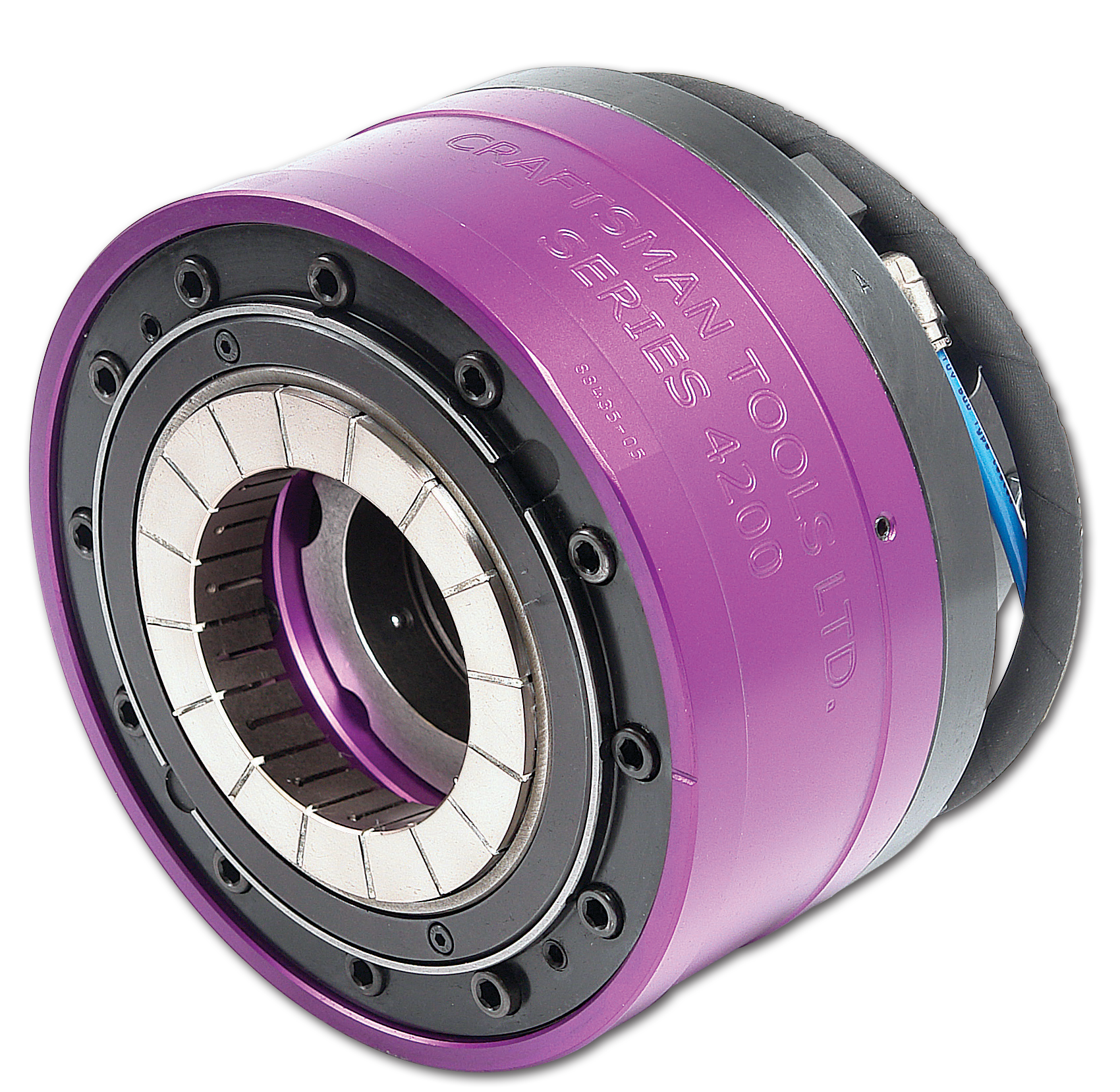

Craftsman Tools is a UK-based, family-run precision engineering company, renowned for the design and manufacture of high-performance workholding and fixture devices. These tools are essential in machining environments, where they clamp components securely under high forces to ensure a high-precision finish.

One of the company’s established product ranges, collets, has been widely used in the production of internal combustion engine (ICE) components, such as crankshafts and camshafts. However, as the automotive industry transitions to EVs, so too must the focus of suppliers.

“We’ve built our reputation around solutions for ICE manufacturing,” explains Tim Thorburn. “But as the industry shifts, we saw an opportunity to evolve.”

Engineering for the EV era

EVs require a significantly higher number of splined components, which interlock like bike gears to transfer rotational force. These components are critical to the functioning of EV powertrains and differ substantially from traditional ICE parts in both shape and engineering requirements.

“Our existing collets are designed for round, smooth components. Splined parts present a completely different set of challenges when it comes to gripping them securely and accurately.”

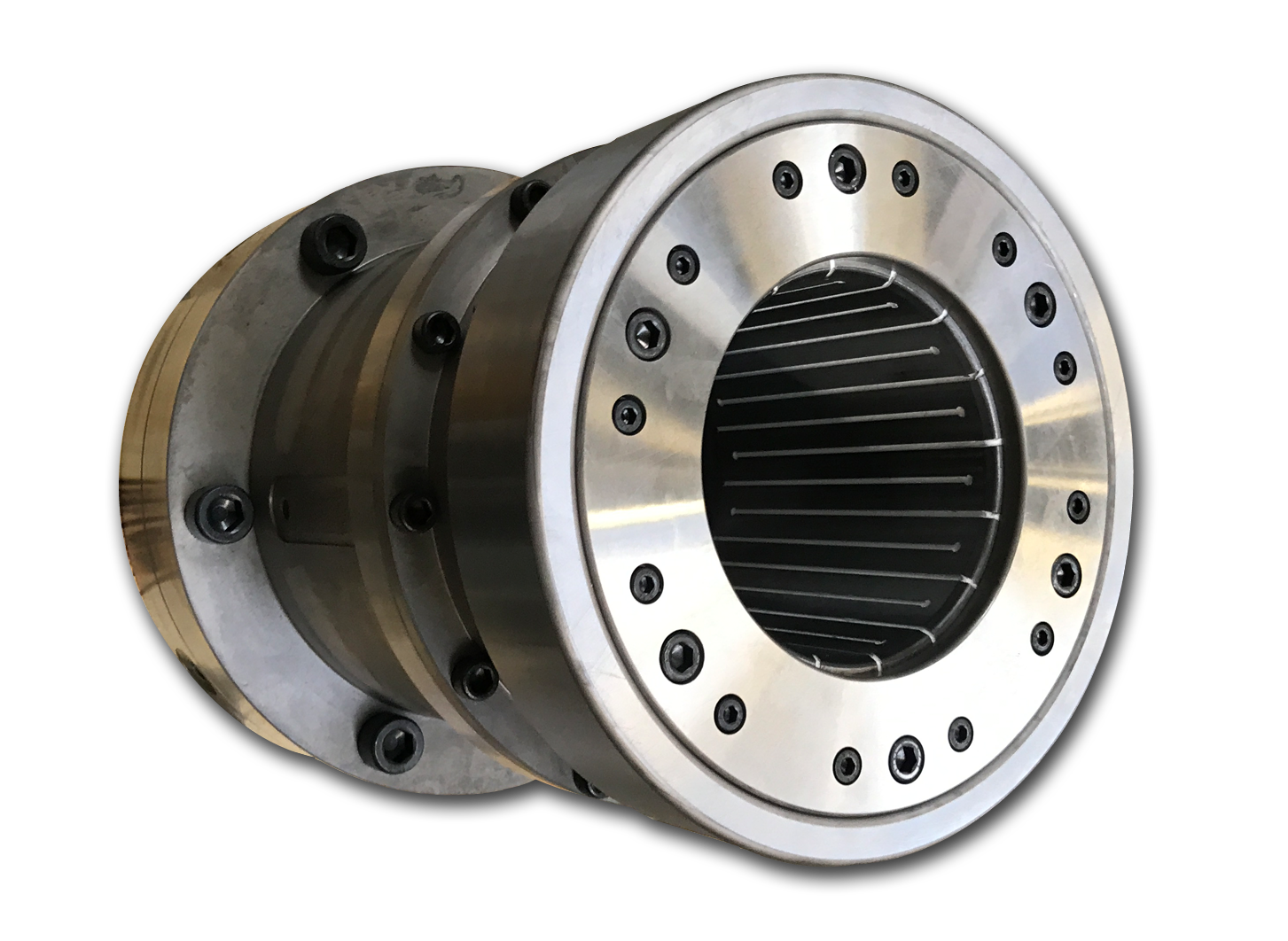

To address this, Craftsman Tools developed a new circular-formed splined collet. This design incorporates mating splines into their existing collet system and can be adapted for a wide range of component sizes. However, there were still technical questions to answer. Would the collet hold the splines securely under machining forces? Could it deform? And how could these performance factors be reliably tested?

Testing, validation and collaboration

Craftsman Tools turned to the University of Huddersfield through the I4M programme to answer these questions. Together, they developed a specialised test rig to simulate the conditions and forces experienced during spline machining.

A splined test component was clamped into the collet and subjected to various loads, replicating typical manufacturing stresses. Measurements were taken throughout the process to evaluate how the spline teeth responded under pressure.

The results were promising. Initial tests showed that the collet could withstand forces typical in machining environments, with minimal slippage or deformation. This gave the Craftsman team confidence that the design would meet the demands of EV manufacturing.

The project also led to the development of a measurement method that could be implemented in-house using Craftsman Tools’ existing equipment. This allowed the team to inspect and verify spline integrity without investing in costly new metrology systems.

“The teams at Huddersfield and NPL were fantastic,” says Tim Thorburn. “They understood our products and the engineering behind them, and they found solutions quickly.”

Market impact and future growth

Thanks to the I4M support, Craftsman Tools now has a validated product ready for the growing EV market. The new collet system can be certified to meet the torque and force requirements specified by EV manufacturers, supported by data-backed safety limits. This gives customers confidence in both the performance and reliability of the system.