Precision and efficiency from day one with Creaform MetraSCAN from MSL

JOTA Composites is a specialist manufacturer of high-quality, autoclave-cured composite components, supporting a range of industries including automotive, defence, marine and motorsport. Although a relatively new entity within the established JOTA Group, a company with a rich heritage in motorsport and advanced engineering, JOTA Composites brings together decades of expertise in the composites sector.

As 2025 marks JOTA’s 25th anniversary, it celebrates not only a quarter of a century of motorsport achievements but also the enduring commitment to engineering excellence that has shaped the company’s journey. Founded in 2000, JOTA has built an unrivalled reputation in the automotive engineering and motorsport industries, where every milestone is fuelled by the passion and drive that defines the ‘JOTA way’.

As an expert in working with advanced materials such as carbon fibre, aramids and sustainable alternatives, JOTA Composites delivers complex, precision-engineered solutions tailored to each project’s needs. Providing full project management, the company oversees every stage of production, from initial concept through to final delivery. This end-to-end approach ensures components are produced to the highest standards, delivered on time and within budget, with a focus on accuracy, durability, and performance.

Objectives

As a newly formed company, JOTA Composites aimed to establish itself as a leader in composite manufacturing by achieving precision, efficiency and high-quality output from day one. The company recognised the competitive nature of the industries they serve and sought to differentiate themselves with cutting-edge technology and seamless inspection processes.

To support its goals, the company aimed to invest in advanced metrology technology that would reduce production errors, accelerate project timelines, and eliminate the need for multiple pieces of equipment. The technology needed to integrate into its workflow, enabling the skilled team at JOTA Composites to perform accurate inspections with minimal downtime.

By selecting a best-in-class scanning solution, the company set the foundation for growth, aiming to support a variety of sectors beyond motorsport, including aerospace, defence and bespoke manufacturing.

Application areas

JOTA Composites specialises in delivering high-precision composite solutions for a range of industries that require performance, durability, and accuracy. Drawing from its strong roots in motorsport and advanced engineering, the company’s expertise has expanded into sectors where lightweight, high-strength components are critical. JOTA Composites serves the following key sectors:

- High-end automotive: Manufacturing lightweight, high-strength components for performance vehicles and hypercars;

- Motorsport: Delivering advanced composite solutions to racing teams;

- Aerospace and defence: Providing lightweight, durable components for aerospace and defence, designed to withstand extreme conditions;

- Bespoke projects: Engaging in unique, high-end custom projects, including luxury furniture and architectural elements, that combine aesthetics with strength and performance.

By integrating the Creaform MetraSCAN from Measurement Solutions Ltd (MSL) into its processes, JOTA Composites ensures that all components meet precise specifications, driving efficiency and consistency across their projects.

Challenges

As a new player in industries where precision is critical, JOTA Composites faced several challenges in adopting conventional scanning methods:

- Multiple equipment requirements: Without an advanced metrology system, JOTA would have needed multiple tools to achieve the desired precision, resulting in higher complexity and costs;

- Inefficient inspection processes: Using traditional measurement tools would have led to slower, less efficient inspections, potentially causing delays in production;

- Risk of inaccuracies: Precision is crucial in high-performance industries, where even small deviations in measurement could affect the final product’s performance, safety, and reliability;

- Long-term operational costs: While initially costly, using multiple tools would have led to inefficiencies and higher long-term expenses, including material waste and rework.

Recognising these challenges early, JOTA Composites made the strategic decision to adopt the Creaform MetraSCAN from MSL, an all-in-one solution that offers high accuracy and flexibility, ensuring efficient and accurate workflows from day one.

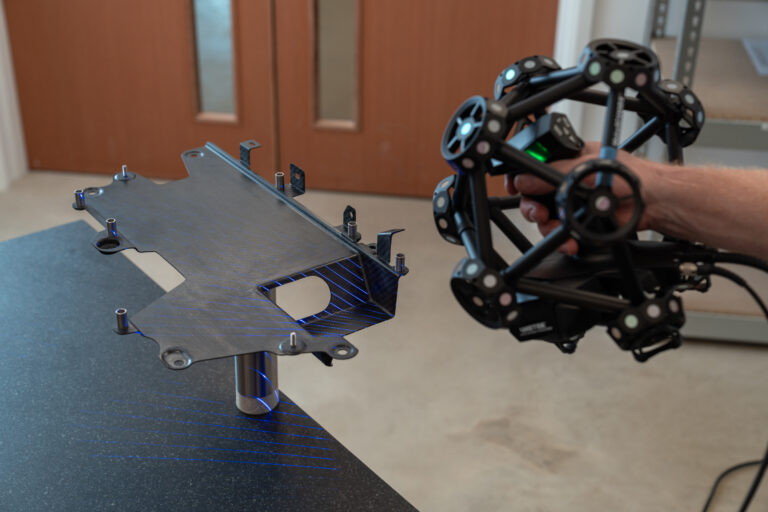

Solution: Creaform MetraSCAN

Having extensive experience with Creaform’s MetraSCAN, the JOTA Composites team opted to integrate it into their workflow from the outset. This decision was based on several factors:

- High accuracy: The MetraSCAN offers exceptional precision, ensuring that each component meets the exact specifications required for high-performance applications;

- Flexibility and portability: Its mobility allows for quick inspections across various projects and locations;

- Cost efficiency: Despite the initial investment, the MetraSCAN eliminates the need for multiple tools, providing long-term savings;

- Expertise and familiarity: Having used the MetraSCAN in the past, the JOTA team was able to integrate it smoothly into the company’s workflow, ensuring immediate operational benefits.

Benefits

Investing in the Creaform MetraSCAN has provided JOTA Composites with a range of advantages that directly impact its efficiency, quality and overall competitiveness. By integrating a high-precision 3D scanning solution into the company’s workflow, JOTA has been able to maintain the highest standards expected in high-performance industries. The benefits extend beyond just measurement accuracy, influencing broader operational efficiencies, cross-team collaboration and long-term cost savings.

Key benefits include:

- Immediate implementation and results: By integrating the MetraSCAN from day one, JOTA Composites eliminated the learning curve and inefficiencies often associated with new technology adoption;

- Cross-group utilisation: The MetraSCAN is utilised across the Jota Group, ensuring consistency and interoperability between different teams and projects;

- Optimised inspection process: The accuracy and speed of the MetraSCAN streamline quality control, reducing delays and enhancing productivity;

- Competitive advantage: The ability to offer precision composite solutions with rapid turnaround times sets JOTA Composites apart from competitors.

Results

The integration of the Creaform MetraSCAN has led to measurable improvements in operations, including:

- Increased efficiency: Faster inspections have resulted in shortened project timelines;

- Reduced costs: The MetraSCAN’s versatility and accuracy eliminate the need for multiple scanning tools, leading to cost savings;

- Enhanced quality assurance: High-precision scanning ensures that components meet industry standards, maintaining the company’s reputation for quality;

- Scalability and flexibility: The portability of the MetraSCAN has enabled its use across different sites and projects, supporting Jota’s growth into new sectors.

Testimonial

Matt Cox, Director at Jota Composites, says: “From day one, we knew we needed the best technology to meet the demands of our high-end clients. Having used Creaform MetraSCAN before, it was an easy decision. The accuracy, flexibility, and efficiency it provides have been instrumental in ensuring our success. It’s not just about making an investment in equipment; it’s about investing in precision, reliability, and long-term growth.”

Final outcome

By adopting the Creaform MetraSCAN, JOTA Composites positioned itself as a leader in composite manufacturing, able to meet the stringent demands of sectors like motorsport, automotive, aerospace and defence. The integration of this cutting-edge technology streamlined its inspection and quality assurance processes while also future-proofing operations. This has allowed the company to scale seamlessly as it expands into new sectors, enhancing collaboration within the JOTA Group and reducing inefficiencies across projects.

JOTA Composites has now established itself as an agile, technology-driven company, differentiating itself in the market by leveraging innovation to stay ahead of the competition.