Precision and efficiency: Visit Measurement & Inspection Zone at MACH 2026

In modern manufacturing, precision is not just a goal but a necessity. Accurate measurement and inspection underpin every successful production process, ensuring efficiency, compliance and quality. At MACH 2026 (Birmingham NEC), the Measurement & Inspection Zone will highlight the latest advancements in metrology and quality control, providing manufacturers with the tools needed to optimise performance and maintain a competitive edge.

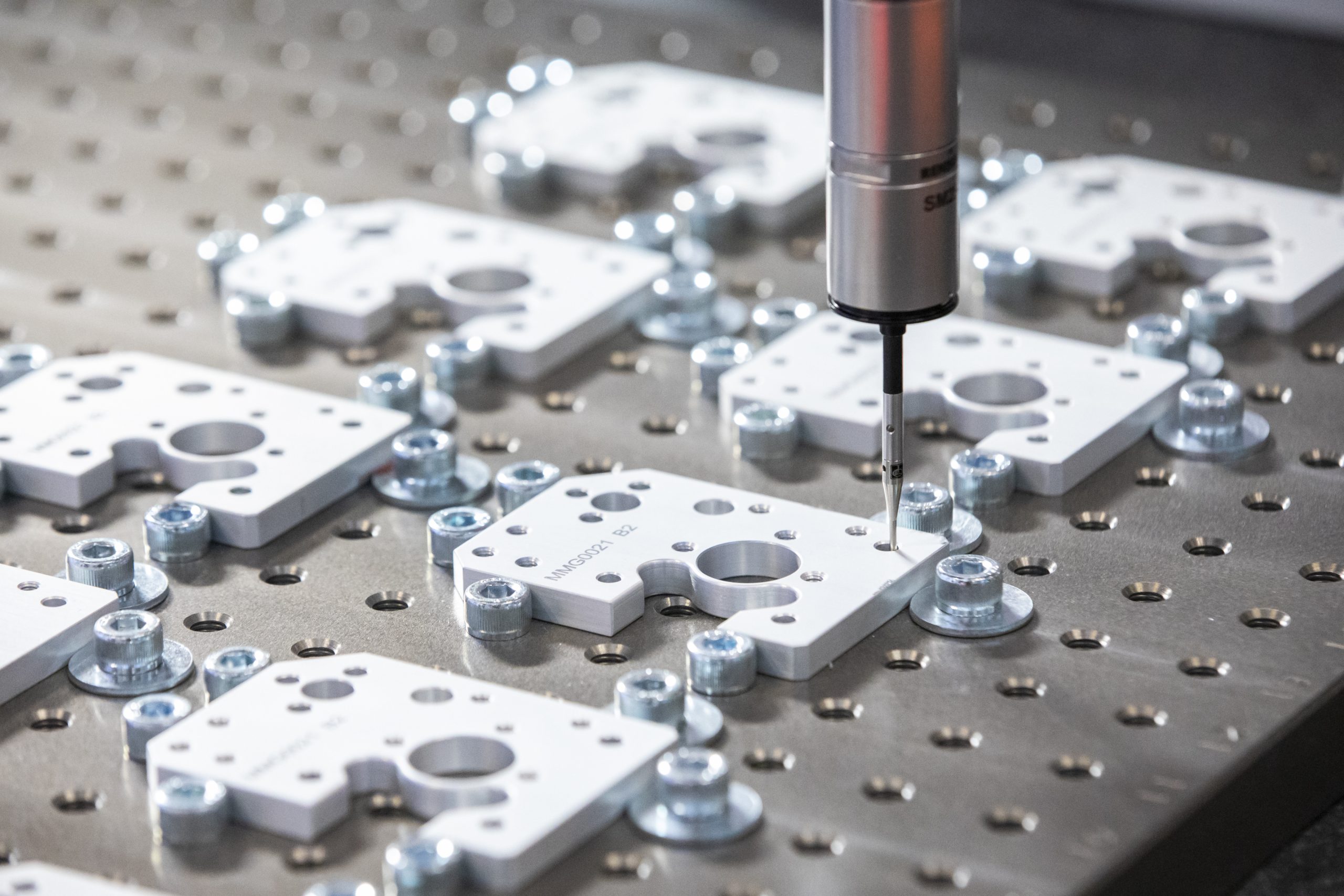

Manufacturing efficiency cannot be assessed without the ability to measure and inspect components precisely. As production processes become increasingly complex, integrating advanced metrology is critical. The ability to verify machining accuracy, collect digital data for real-time process improvements, and implement high-precision quality control measures is essential for manufacturers striving for excellence.

The Measurement & Inspection Zone at MACH 2026 presents a unique opportunity for industry professionals to connect with world-class innovators and explore the latest advancements shaping the future of metrology.

The Measurement & Inspection Zone, always the largest zone at the exhibition, will once again be located in Halls 19 and 18, and will feature a range of exhibitors showcasing CMMs, laser scanning, optical inspection and non-contact measurement technologies. These solutions provide manufacturers with the capability to ensure accuracy and compliance through advanced measurement tools, enhance productivity with digital data collection, and gain a competitive advantage through step-change improvements in quality control and precision engineering.

As the UK’s leading event for manufacturing and engineering, MACH 2026 will bring together cutting-edge technologies and industry leaders. The Measurement & Inspection Zone will provide a dedicated space for businesses to explore the latest innovations in precision engineering, helping them to improve production quality and efficiency.