Precision under pressure: How magnescale feedback system enhances rolling mill performance

In the high-stakes world of metal processing, precision and durability are non-negotiable. Rolling mills operate under intense mechanical stress, extreme temperatures, and constant vibration—conditions that demand robust, high-resolution feedback systems to maintain quality and efficiency. With this in mind, Innovative Measurement Technology is now offering the Magnescale feedback scale system, a purpose-built solution engineered to thrive in the harshest industrial environments.

Built for the rolling mill

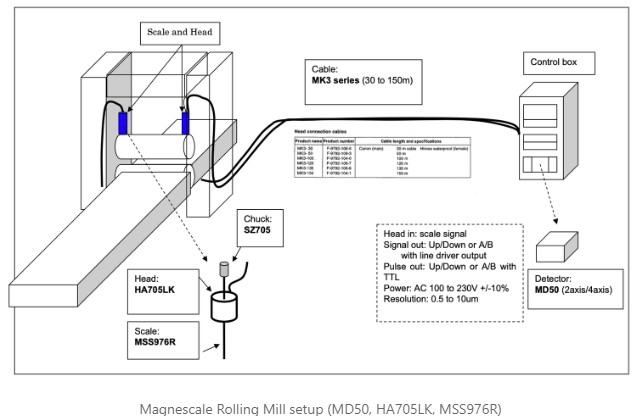

The Magnescale system combines the HA-705LK reader head, MSS-976R scale rod, and MD50 interpolator to deliver:

- 🎯 ±3µm accuracy and up to 0.5µm resolution;

- 🛡️ IP67 waterproofing, shock resistance up to 110G, and vibration tolerance up to 50G;

- 🔄 Real-time position feedback for precise control of rolling operations;

- ⚙️ Two- or four-axis control with flexible integration into custom automation racks;

- 🌍 Global voltage compatibility and trusted performance in steel, aluminium and non-ferrous mills.

Why it matters

Rolling mills rely on accurate position feedback to control roll gaps, monitor material thickness and ensure consistent product quality. The Magnescale system provides:

- Real-time feedback to reduce waste and improve throughput;

- Extreme durability to withstand coolant, debris, and mechanical shock;

- Flexible integration with modern control systems and legacy infrastructure.

Whether upgrading an existing line or building a new facility, this system offers a future-proof solution for high-precision metal processing.