Centreless run-out testers aleviate measurement bottlenecks

In precision manufacturing, even the smallest deviation can lead to costly defects, rejected parts and delayed deliveries. Traditional run-out measurement methods are often slow, complex and require specialised training, creating bottlenecks during set-up operations. Spreitzer’s centreless runout testing devices are changing this predicament.

With these systems, run-out tests can be completed in just 10 seconds, directly at the machine and without prior knowledge. This efficiency reduces defect costs, acclerates production and ensures consistent quality, improving customer satisfaction.

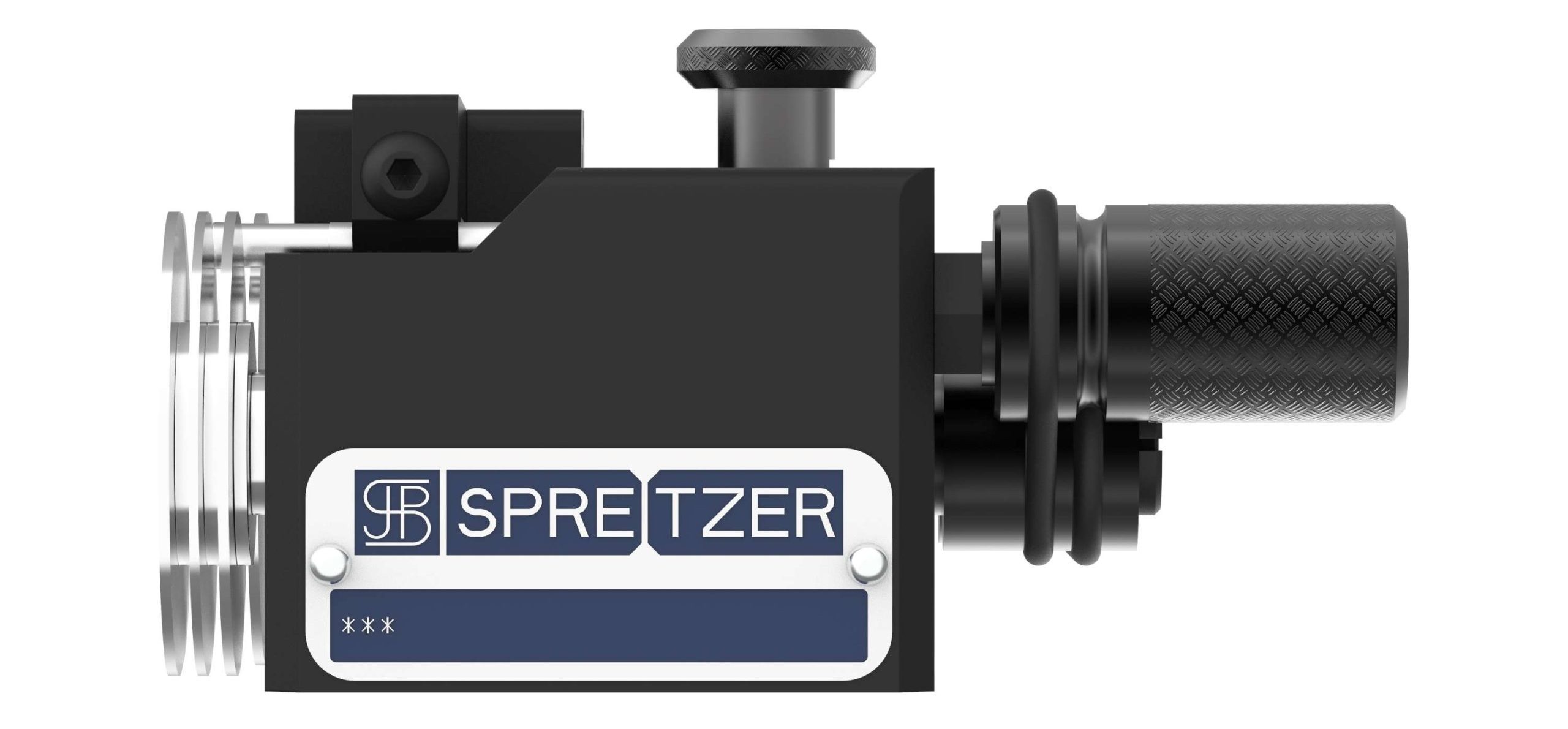

Spreitzer offers tailored solutions for different applications. The RPG Mini is suitable for workpieces under a measurement optics, while the RPG AL excels in single-piece measurements. The company also offers the RPG, which is designed for series inspections.

Each model is intuitive and easy to use, allowing teams to conduct precise measurements quickly. By integrating these devices, Spreitzer says manufacturers can save time, reduce costs and deliver high-quality components, strengthening customer relationships and securing more orders.