Smart sensing keeps tool changes smooth

A recent automation project has transformed tool changing on hydraulic presses used in the moulding of automotive body panels. By integrating a single Contrinex inductive sensor, engineers have achieved faster, safer and more efficient operations, proving that even a small technological upgrade can deliver a significant impact.

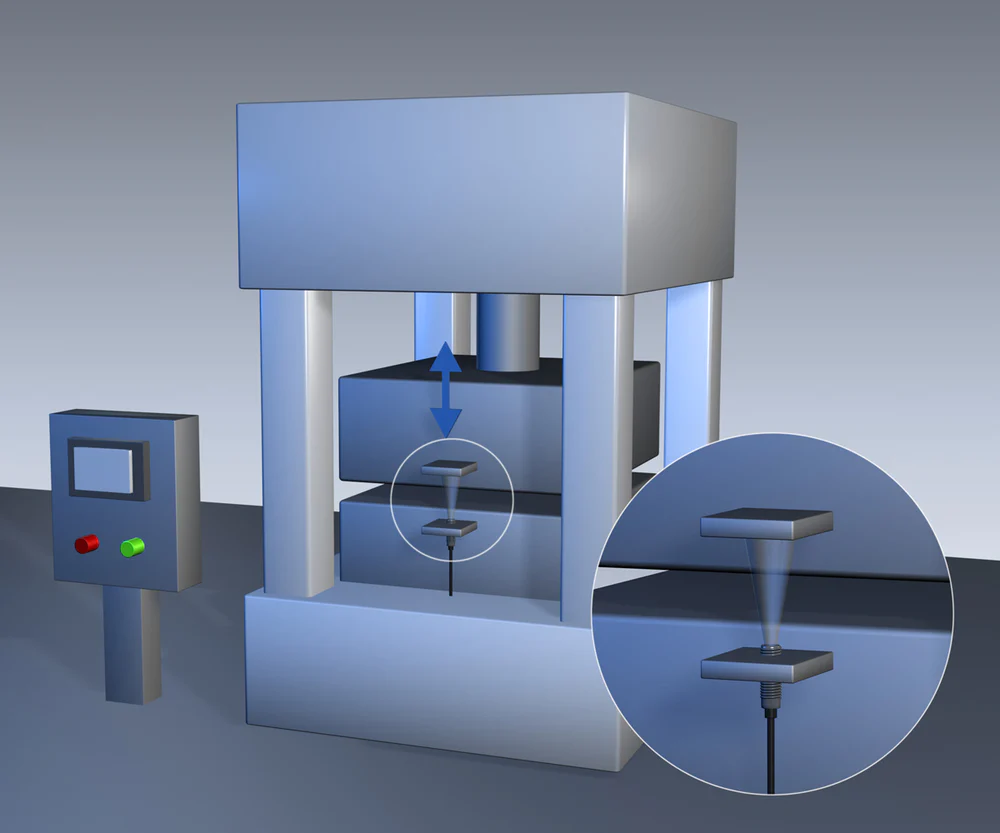

Hydraulic presses are a mainstay of automotive production, shaping metal panels with precision and power. These down-acting machines use hydraulic rams to bring the upper die down onto the lower tool half, forming the required part. However, one of the most critical and non-productive stages in this process is the tool-change sequence.

During a tool change, the upper die must detach from the ram and carefully reposition before removing the complete toolset. Before this can begin, it’s essential that both tool halves are perfectly closed and aligned. Any deviation risks severe damage to expensive tooling or the press itself, resulting in costly downtime and repair work.

A smarter, simpler solution

To eliminate this risk and streamline the changeover, engineers selected a robust sensing solution from Contrinex. The DW-AS-603-M18-002 inductive sensor was chosen for its proven performance and durability in demanding industrial environments. Mounted on an angle bracket on the lower tool housing, it detects a target bracket on the upper die. Only when the two tool halves are completely closed does the sensor send a confirmation signal to the press control system, allowing the tool-release sequence to proceed.

This precise detection ensures that the upper tool can only be detached when perfectly aligned. The result is consistent, error-free operation. By automating this critical verification step, the system removes the potential for human error, protects valuable assets and maintains the high-speed efficiency required in modern automotive manufacturing.

Reliable performance for Industry 4.0

Engineered for reliability, the Contrinex inductive sensor operates effectively in harsh production conditions, with a temperature range from -25°C to +70°C. It provides fast, accurate detection and an extended sensing range at low cost. With IO-Link compatibility, the technology is also suitable for integration into Industry 4.0 systems.

This project demonstrates how a straightforward sensing solution can make a measurable difference to press safety, reliability and productivity across automotive manufacturing environments.