Unlocking speed, accuracy and innovation with the HandySCAN Silver Elite

Pyramid Moto (Pyramid Plastics UK Ltd) is a second-generation, family-run business based in Gainsborough, Lincolnshire. Since 1986, Pyramid has been at the forefront of aftermarket motorcycle accessory design, offering a vast range of aesthetic and protective parts, including huggers, Extenda Fendas, belly pans, seat cowls, engine covers, and luggage solutions. All product development is carried out in-house, with the Creaform HandySCAN Silver Elite supplied by Measurement Solutions Ltd (MSL) now a core part of Pyramid’s R&D and design workflow.

With a catalogue of over 25,000 parts and distribution partnerships with brands like Puig, Ermax, and GBRacing, Pyramid has built a global reputation for quality, innovation and rider-focused design.

Objectives

Pyramid wanted to boost the speed and accuracy of its product development. With its expansion into more complex product lines and multi-material components, legacy methods like clay form modelling, manual measurement and phone-based scanning were slowing the company down and introducing accuracy issues.

The goal was to:

- Eliminate slow, manual clay modelling and unreliable phone-based scanning

- Improve first-time accuracy in part development

- Accelerate time-to-market for new accessories

- Increase design responsiveness to customer and market demands

- Create a digital product development pipeline suitable for a fast-moving, highly competitive motorcycle accessory market.

Applications

The HandySCAN Silver Elite is used to:

- Digitise new motorcycles: high-resolution 3D scans of project bikes form the basis of accessory design

- Accelerate prototyping: enable precise CAD modelling without relying on guesswork or trial-and-error

- Validate geometry: identify hard-to-see or hidden components early, reducing the risk of design issues

- Respond to market demand: scan customer bikes on-site to assess interest and develop parts based on multiple requests

- Build a digital design library: maintain a central archive of CAD-ready scan data for repeat production.

The HandySCAN Silver Elite has become a regular and essential tool within Pyramid’s product development workflow. While its usage varies depending on the stage of development, it’s typically deployed several times each week, particularly during the early phases of new product design.

During periods of high activity, such as when multiple project bikes are being developed simultaneously, the scanner is used daily to capture critical geometry, validate fitment areas and revisit specific components as designs evolve. This flexible, on-demand use ensures the team can move quickly from concept to CAD, regardless of project complexity or volume.

The challenges

Before investing in the HandySCAN Silver Elite, Pyramid relied on a combination of manual modelling techniques and basic consumer-grade technology to develop new motorcycle accessories.

While these methods had served the business for years, they began to reveal serious limitations as Pyramid pushed into more complex designs and sought to reduce development cycles.

The lack of accurate, efficient tools not only impacted internal workflow but also put the company at a disadvantage in an increasingly competitive market. Specific challenges included:

- Manual clay modelling was labour-intensive, messy and imprecise

- Phone-based scanning apps lacked fidelity and created alignment headaches

- Design errors were common due to missed features, leading to rework and wasted tooling costs

- Time to market was slow, and competitors often launched similar parts before Pyramid could respond

- Customer demand for bespoke parts couldn’t always be met efficiently without fast, accurate scanning tools.

The solution

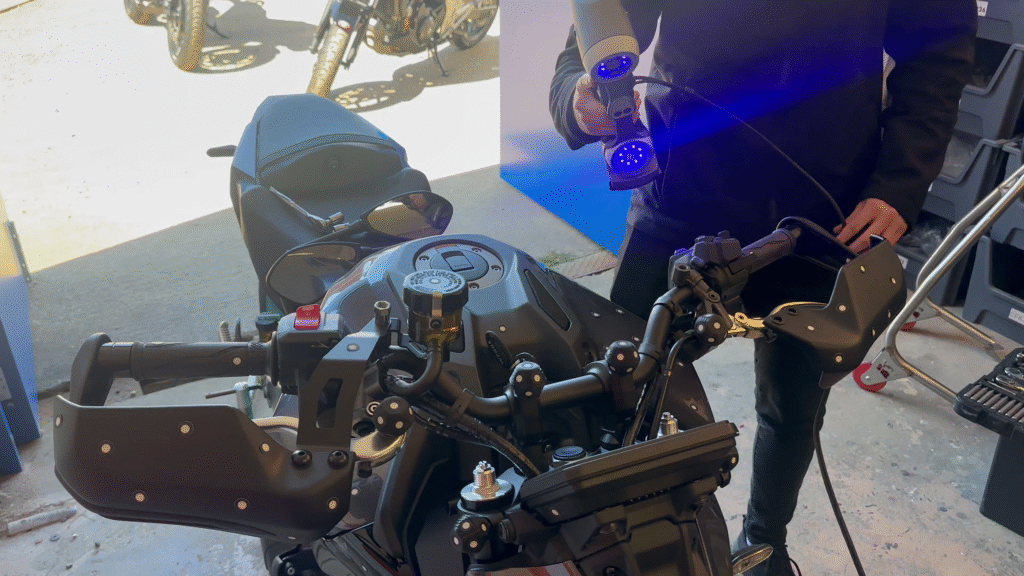

The Pyramid team adopted the Creaform HandySCAN Silver Elite, a handheld, metrology-grade 3D scanner suitable for capturing complex geometries directly on motorcycle bodies.

This system allows Pyramid’s design team to scan bikes quickly and accurately without disassembly or surface preparation. Data is then processed in Fusion 360, the company’s standard CAD platform, to model everything from huggers and body panels to seat cowls and fairings with confidence and speed.

HandySCAN Silver Elite

The Silver series offers a portable, plug-and-play solution that requires no fixed set up or calibration, but does rely on reflective positioning targets for accurate tracking, making it well-suited for workshop environments and scanning directly on motorcycles.

Benefits

The adoption of the HandySCAN Silver Elite has had a transformative impact on Pyramid’s design and development process. By replacing slow, manual methods with fast, highly accurate 3D scanning, the team has streamlined its workflow, reduced reliance on guesswork and significantly improved its ability to respond to market demands.

What began as a tool to accelerate prototyping has evolved into a cornerstone of Pyramid’s product innovation strategy, supporting everything from initial concept development to bespoke customer requests. The results have been clear across multiple areas:

Time savings

- Parts like rear huggers, which previously took 7–10 days using clay or mobile scanning, are now completed in 2 days or less

- Fewer physical prototypes and iterations required

Increased accuracy

- Scans capture fine detail across bodywork, hidden features and mounting points

- Designers no longer miss critical geometries or need to reverse-engineer by eye

Faster time-to-market

- Pyramid is now launching new products in parallel with competitors, sometimes even faster

- This agility has helped the brand stay top-of-mind with retailers and riders alike

Improved workflow efficiency

- Scans integrate directly into Pyramid’s Fusion 360 CAD workflow

- A digital archive of part data supports repeat orders and efficient updates

Market responsiveness

- On-the-fly scanning of customer bikes enables quick assessment of bespoke part feasibility

- Helps uncover unmet needs that can be scaled into new product lines

The results

The HandySCAN Silver Elite has helped Pyramid transform its development cycle into a faster, more precise and more scalable process. Instead of losing market share due to delays, Pyramid now competes confidently, often becoming the first to release a new fitment for a specific bike model.

The final outcome

The integration of the HandySCAN Silver Elite has made high-precision 3D scanning an essential part of Pyramid’s product development. The result is a leaner, faster, and more innovative design process that supports the company’s growth and maintains its position as a respected UK manufacturer in the global motorcycle accessories market.

Pyramid continues to invest in digital tools that empower its team to design with precision, respond with agility and deliver with confidence, all while proudly keeping production in the UK.

Says Sam Wilkins, Product Design Manager at Pyramid Moto: “We would previously spend up to two weeks modelling something like a hugger using clay or basic phone scanning. Now, with the HandySCAN, we can get a usable result in just a couple of days. It’s made a massive difference, not only in time savings, but in the confidence we have in each design.”