What applications can benefit most from a Hawkeye V3 video borescope?

The Hawkeye V3 Video Borescope, developed by Gradient Lens Corporation, is an inspection tool designed for a range of applications that require detailed visual inspection of internal structures. The videoscope combines advanced imaging technology with robust construction, making it an excellent choice for industries that need precise and reliable inspection capabilities. Availability in the UK is via Optimax Imaging and Inspection, which sets out the best use cases for the Hawkeye V3 video borescope.

Aerospace industry

o Engine inspection: The Hawkeye V3 is suitable for inspecting aircraft engines, including turbines and combustion chambers. Its high-resolution imaging helps detect cracks, corrosion and other defects that could compromise safety.

o Airframe inspection: Inspecting airframes for structural integrity ensures there are no hidden issues that could lead to failure.

Automotive industry

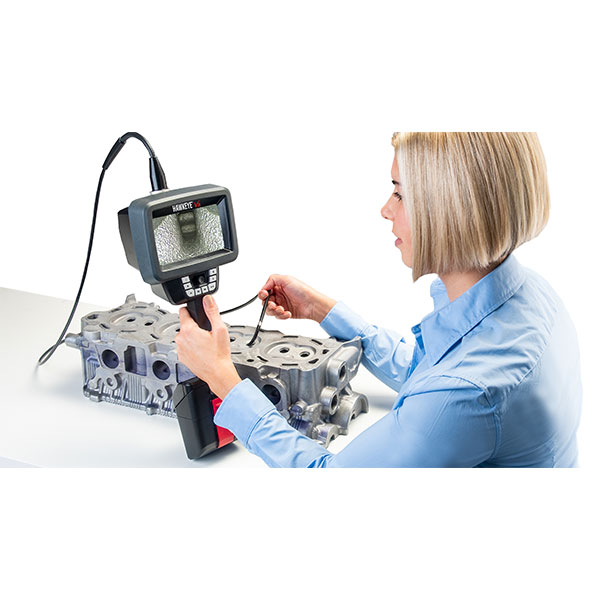

o Engine and transmission inspection: Automotive technicians can use the Hawkeye V3 to inspect internal engine components, transmission systems and other hard-to-reach areas without disassembly.

o Quality control: Inspecting manufactured parts for defects prior to assembly meets quality standards.

Oil and gas industry

o Pipeline inspection: The videoscope can inspect pipelines for corrosion, cracks and blockages, helping to maintain system integrity.

o Downhole equipment inspection: Inspecting drilling equipment and downhole tools for wear and tear ensures they are in good working condition.

Power generation

o Turbine inspection: Inspecting turbines and other power generation equipment ensures the identification of defects that could affect performance and safety.

o Boiler inspection: Checking the internal condition of boilers ensures they are free from scale, corrosion and other issues.

Manufacturing

o Quality assurance: The Hawkeye V3 is useful in various manufacturing processes for inspecting the internal components of machines and finished products to ensure they meet quality standards.

o Maintenance and repair: Inspecting machinery and equipment for wear, damage or potential failure points, contributes to preventative maintenance strategies.