Why manufacturers benefit from combining in-house and outsourced metrology

Accurate measurement underpins every stage of modern manufacturing. From early design and prototyping to tooling validation, production control and final inspection, high-quality data ensures decisions are reliable and products meet specifications. As the complexity of products increases and supply chains become more demanding, many manufacturers now take a hybrid approach to metrology, combining the speed and convenience of in-house capability with the expertise, capacity and advanced technology available through outsourced services.

It’s not a case of one approach being ‘better’ than another. In reality, the manufacturers with the strongest metrology outcomes are those who use both strategically. This article explores the strengths of each approach, how they complement one another, and the role Measurement Solutions Ltd (MSL) plays in helping companies build a flexible, resilient measurement capability.

The strengths of in-house metrology

Building internal metrology capability gives manufacturers direct control over day-to-day quality processes. Routine checks, in-process verification and quick investigations can be carried out immediately, without relying on external availability. This rapid feedback loop is particularly valuable on the production line, where delays can quickly escalate into downtime or scrap.

Having systems on-site also allows engineering teams to validate their own work as they go. Whether they’re fine-tuning a fixture, evaluating a tooling tweak or validating a prototype, immediate access to measurement accelerates problem-solving and speeds up development cycles.

In-house metrology also plays a crucial role in supplier management. Parts can be checked on arrival, ensuring conformance before production begins. And for repeatable, high-volume inspection tasks, internal workflows are often the most cost-efficient route, with a very low cost-per-measurement once processes are established.

Over time, internal teams also build invaluable knowledge about their own parts and processes. They understand how components behave during manufacturing, where tolerances are most sensitive, and how variation typically presents. This insight is difficult to replicate externally and helps teams make better engineering and production decisions.

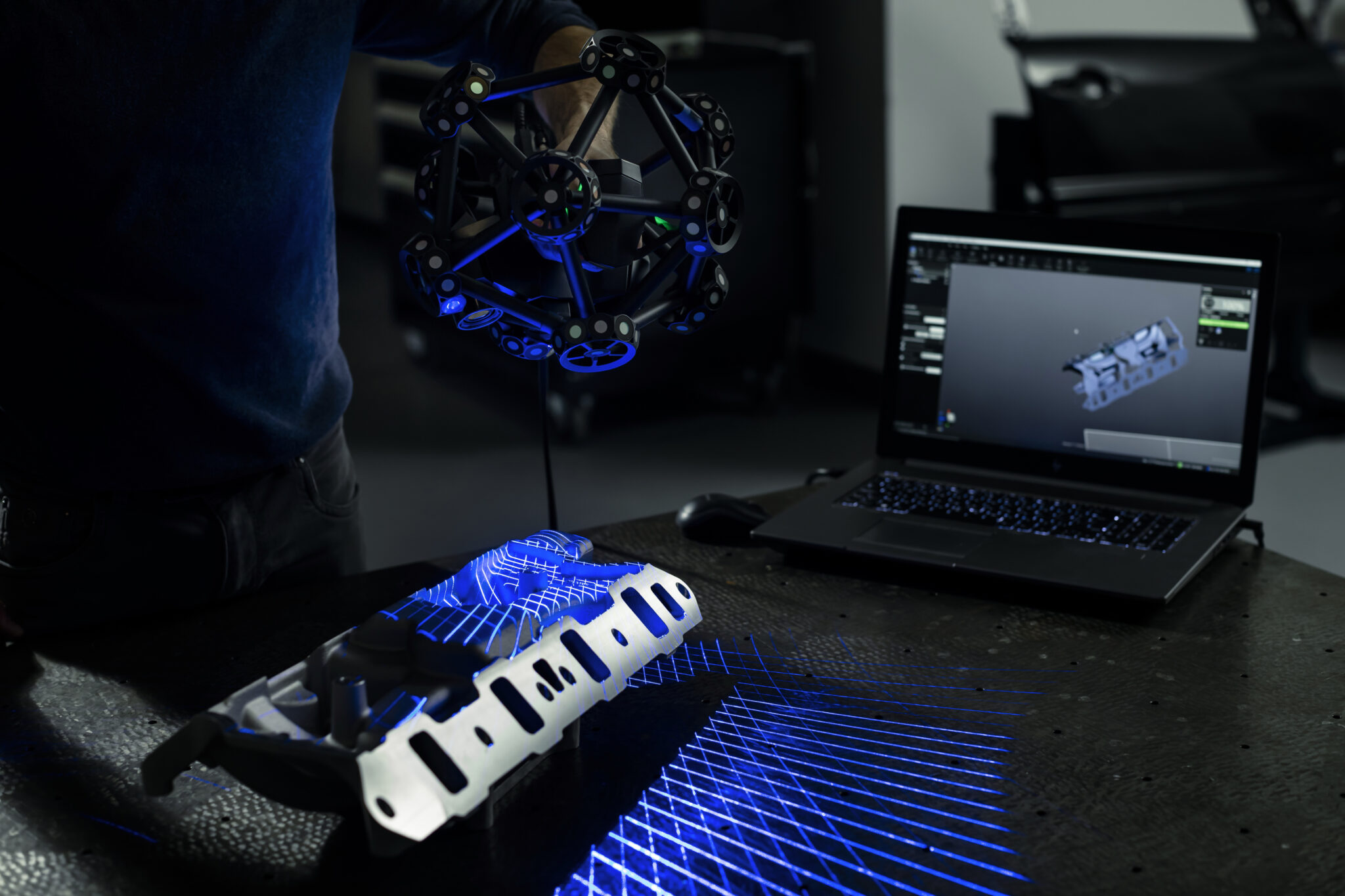

MSL supports this internal capability through the supply of portable 3D scanners, optical systems, metrology software, calibration support, training and on-site workflow optimisation. Yet even with strong internal systems, there are many situations where outsourcing becomes the more effective choice.

Where outsourced metrology complements in-house capability

Outsourcing is not a substitute for internal metrology; it’s an extension of it. Manufacturers typically rely on external services when deadlines tighten, workloads increase, or specialist expertise is required.

One of the most common scenarios is simple workload pressure. During peak production periods, supplier transitions, tooling changes or NPI phases, in-house teams can quickly reach capacity. Outsourcing provides immediate relief, allowing critical work to continue without slowing down production or extending lead times.

Manufacturers also turn to outsourced metrology when dealing with complex or unfamiliar tasks. Large structures, composite components, thin-wall parts, flexible materials, intricate assemblies and high-accuracy investigations often require advanced workflows or technologies that may not exist internally. Reverse engineering into editable CAD, for example, benefits from specialist software and highly experienced engineers who can produce clean, usable models quickly and reliably.

Outsourcing is also a practical way of accessing high-end technology without committing to capital expenditure. Advanced systems such as optical-tracked scanning, large-volume measurement platforms or ultra-high-precision inspection tools are not required every day. External support allows manufacturers to use these technologies only when the task demands it.

When production issues arise unexpectedly, an assembly not fitting, tooling drifting out of tolerance, or a previously stable process beginning to vary, outsourced specialists can diagnose the issue quickly and objectively. With broad exposure to different parts and industries, they can often identify root causes faster than an internal generalist team.

And for projects where accuracy, traceability or impartiality is essential, such as safety-critical components, regulatory submissions, warranty cases or supplier disputes, third-party verification provides an independent, defensible assessment backed by formal reporting.

The benefits of combining both approaches

Manufacturers gain the most value when they treat metrology as a hybrid capability, using each method where it delivers the greatest impact.

Routine inspection, daily validation and high-volume repeatable checks naturally sit within the in-house team, ensuring continuity and speed. Outsourcing, meanwhile, fills the gaps, tackling specialist tasks, high-pressure deadlines, detailed investigations or anything requiring additional resources or advanced technology.

This balance ensures companies do not overspend on equipment they only need occasionally, yet still have access to the tools and expertise required for complex work. It also reduces risk across engineering and production workflows: challenging or ambiguous measurement tasks can be handled by specialist teams, ensuring data is accurate and actionable.

By allowing internal and external measurement efforts to run in parallel, productivity increases significantly. Internal teams remain focused on production-critical priorities while outsourced specialists support more demanding or time-sensitive needs.

MSL: A partner for both in-house and outsourced metrology

MSL is one of the UK’s few metrology providers offering a fully integrated approach across both internal capability-building and outsourced measurement services.

For manufacturers looking to strengthen in-house capability, MSL provides portable scanning systems, optical trackers, metrology and inspection software, calibration and maintenance services, targeted training programmes and on-site workflow optimisation. The company helps teams develop confidence, consistency and long-term operational strength.

For outsourced requirements, MSL delivers comprehensive measurement services including on-site and off-site 3D scanning, first article and production inspection, large-volume metrology, reverse engineering into CAD, GD&T reporting, tooling and assembly investigations, supplier verification and multi-stage engineering projects.

What connects both sides of the MSL offer is its consultative approach. The company helps customers choose the most effective metrology strategy for their scenario, whether that means strengthening internal capability, using outsourced support or combining both. The goal is always the same: to deliver the most efficient, cost-effective route to reliable, decision-ready data.

Conclusion

In-house and outsourced metrology are not competing approaches. They are complementary tools that, when used together, give manufacturers agility, resilience and confidence across the entire product lifecycle. Internal systems deliver speed and independence for everyday tasks, while outsourced services provide advanced technology, additional capacity and specialist expertise when projects demand more.

By working with a partner like MSL, manufacturers can adopt a hybrid metrology model that supports better productivity, reduces risk, and ensures consistently accurate measurement, wherever and whenever it’s needed.